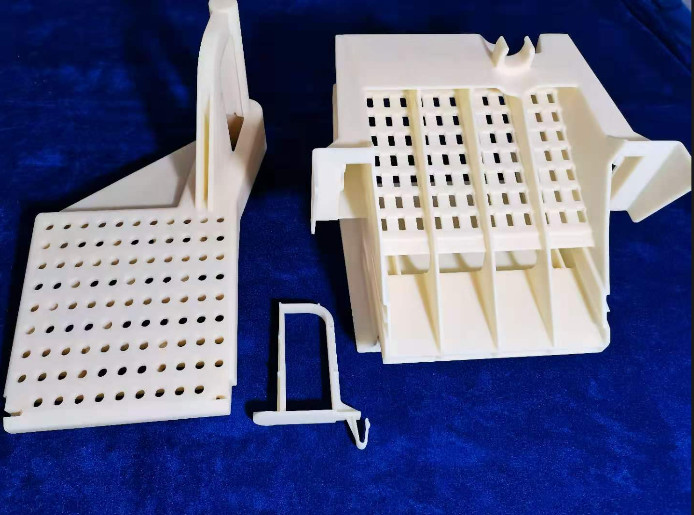

ABS PROTOTYPE

ABS resin easy processing, processing dimensional stability and surface gloss is good, easy to paint, color, can also be sprayed metal, electroplating, welding and bonding secondary processing performance, can be widely used in the field of electrical and electronic, including various office And consumer electronics / electrical appliances, office appliances including electronic data processing machines, office equipment. Now in the electronic and electrical market, ABS resin in the requirements of flame retardant and high heat resistance of the electronics / electrical market will maintain its position, flame retardant and high heat ABS resin and ABS / PC and other engineering plastics alloy competition has obvious Advantage.

ABS material

ABS material universal thermoplastic engineering plastic developed in the 1940s, is a comprehensive mechanical properties of excellent plastic varieties, not only has good rigidity, hardness and processing fluidity, but also has high toughness characteristics, can be injection, extrusion or heat forming. Most of the automotive parts are processed by injection molding, ABS resin has the advantage of impact resistance, sound insulation, scratch resistance, heat resistance better, more beautiful than PP, especially in the transverse impact resistance and the use of temperature More stringent parts. ABS resin is the third largest resin used in cars after polyurethane and polypropylene. ABS resin can be used in the car and the car outside the shell, steering wheel, oil pipe and handle and button and other small parts, including the front of the external radiator grille and lampshade.

In the new product design and development process, ABS prototype is one of the most common prototypes, accounting for about 75% of the total amount of plastic prototype. This is because ABS is a better engineering plastics, the strength can be very good to meet the needs of all kinds of prototype manufacturing. Such as test function, grinding, painting, plating and so on. Polished ABS material, then it is easier, and the surface is also guaranteed to be smooth. And the accuracy is also very good, generally if prototype needs to be painted, chrome plated, and silk screen, then the surface of the sticky is better, to polish very smooth.

ABS material also has impact resistance, with corrosion resistance, can withstand the resistance of low temperature. And the general hot material invasion compared to the official dry applied to home appliances, chassis, toys, automobiles, mechanical instruments and other industries and fields, has become one of the most widely used engineering plastics.

For example, in the prototype processing industry, usually very large ABS plastic prototype are made of ABS material to complete, because the ABS material can be split pieces, and then glued and polished, so as to avoid the overall gong, high cost, risk, or to solve The problem which is the prototype can not be machined since the size is too big. Such as: for manufacturing car dashboard prototype.

ABS material density is generally around 1.2, when the purchase of this material are generally sheet, a large, how much to cut with the number of good. In the processing time, to set aside some borders, about 40mm or so. Processing to complete a surface, need to use gypsum fixed products, and then flip, for another side of the surface processing. Until the product is finished, the knockout of the product is a complete product. After the surface of the grinding and deburring, an ABS prototype is basically completed.

ABS Rapid Prototyping

ABS rapid prototyping can be a very good electroplating and other plastic materials compared to, for example, PC material is difficult to polish smooth, so the plating effect is not very good, but ABS material can be polished very smooth, plating effect is very beautiful. Usually CNC machining ABS prototype is to be processed out if the need for electroplating.

SEND US AN INQUIRY