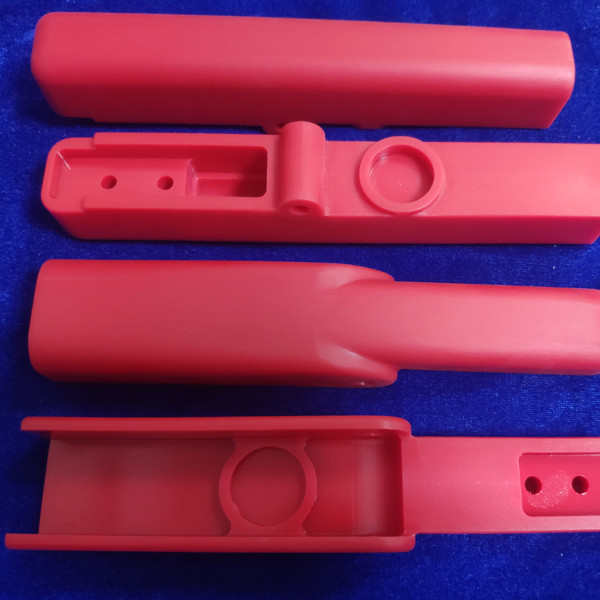

CNC Plastic Machining

CNC plastic machining is a very accurate and efficient way to make plastic parts for a variety of industries, including consumer goods, medical equipment, and the automotive and aerospace sectors. CNC (Computer Numerical Control) machining employs sophisticated software and automated machinery to produce complicated components with remarkable accuracy, in contrast to traditional machining, which necessitates manual modifications.

CNC Plastic Machining: What Is It?

Using computer-controlled equipment to cut, drill, grind, and shape plastic materials into precise forms and dimensions is known as CNC plastic machining. A digital design file (CAD model) is the starting point for the process, which is followed by its conversion into machine-readable instructions. CNC machines consistently produce high-quality parts by precisely following these guidelines.

Benefits

Precision is one of the main advantages of CNC machining. It enables producers to produce intricate details and precise tolerances that are challenging to achieve with human techniques. Other benefits consist of:

- Consistency: Every component made is an exact replica of the original design.

- Flexibility: Compatible with a variety of plastics, including PEEK, ABS, nylon, acrylic, and polycarbonate.

- Scalability: Fits both full-scale manufacturing and prototyping.

- Speed: Quick turnaround in contrast to conventional fabrication techniques.

Smooth finishes are produced by surface quality, which lessens the need for further procedures.

Applications

Numerous sectors employ CNC plastic machining due to its dependability:

- Medical industry: For prosthetic parts, diagnostic tools, and surgical instruments.

- Aerospace: lightweight plastic components for systems and cabin interiors.

- Automotive: Accurate parts for functioning prototypes, lighting systems, and dashboards.

- Electronics: Components for housings, connectors, and insulation.

- Consumer goods: Personalized components for sporting goods, home goods, and other objects.

Comparing Injection Molding and CNC Plastic Machining

CNC plastic machining is an affordable option for companies that require quick turnaround and design flexibility because it does away with the requirement for pricey molds.

Because CNC plastic machining offers unparalleled accuracy, speed, and versatility, it has revolutionized modern production. CNC machining guarantees excellent results that are customized to your requirements, whether you need a single prototype or a batch of unique parts. The preferred option for sectors where accuracy and dependability are essential is CNC plastic machining.