Clear Prototype

Prototypes are essential for turning ideas into physical models in the design and development of products. This is furthered by a clear prototype, which offers transparency to view internal structures, mechanics, or fluid movement in addition to a functional representation of the product. In order to test designs more successfully before going into full-scale production, these prototypes are frequently utilized in industries like consumer electronics, packaging, automotive, and medical devices.

A clear prototype: what is it?

A tangible model of a product created from transparent materials such as acrylic, polycarbonate, or clear resin is called a clear prototype. Manufacturers produce extremely accurate prototypes using cutting-edge techniques like CNC machining, vacuum casting, or 3D printing, enabling engineers and designers to assess the inside functionality as well as the external design.

Benefits of Unambiguous Prototypes

- Visual Clarity: These prototypes’ transparency allows stakeholders to see internal systems and structures.

- Engineers can evaluate fluid or airflow behavior, assembly fit, and moving parts with the aid of functional testing.

- Improved Communication: Offers a practical example for presenting to investors, clients, or colleagues.

- Material Options: For improved performance, long-lasting polymers with optical-grade finishes can be used.

- Cost-effective validation reduces expensive manufacturing changes by detecting design faults early.

Clear Prototype Applications

- Medical Industry: To see how surgical instruments, implanted devices, or diagnostic devices work.

- Consumer electronics: For clear enclosures displaying internal circuit layouts.

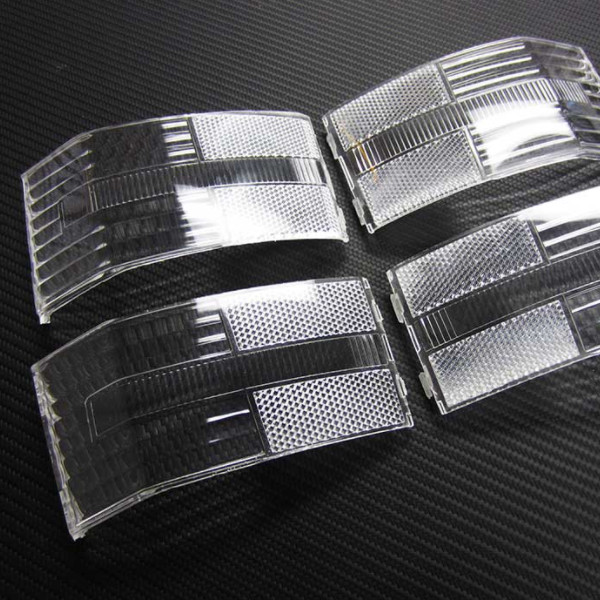

- Automotive: To research fuel flow, fluid systems, or cutting-edge lighting prototypes.

- Clear mock-ups are used in packaging design to evaluate usability, durability, and aesthetics.

- Research and Education: Teaching aids in the clear and intelligible demonstration of mechanisms.

Methods for Manufacturing Clear Prototypes

- High-precision prototypes made from clear acrylic or polycarbonate blocks are produced by CNC machining.

- Vacuum casting produces prototypes with a smooth, glass-like finish and is perfect for small production runs.

- With its quick turnaround time and transparent materials, 3D printing is ideal for testing iterative designs.

A clear prototype is a potent tool that improves testing, collaboration, and creativity. It is more than just a visual model. Clear prototypes guarantee better decision-making in product development by enabling teams to analyze both internal and exterior features. Transparent prototypes, whether for electronics, medical devices, or automotive applications, provide both physical and symbolic clarity to the design process.