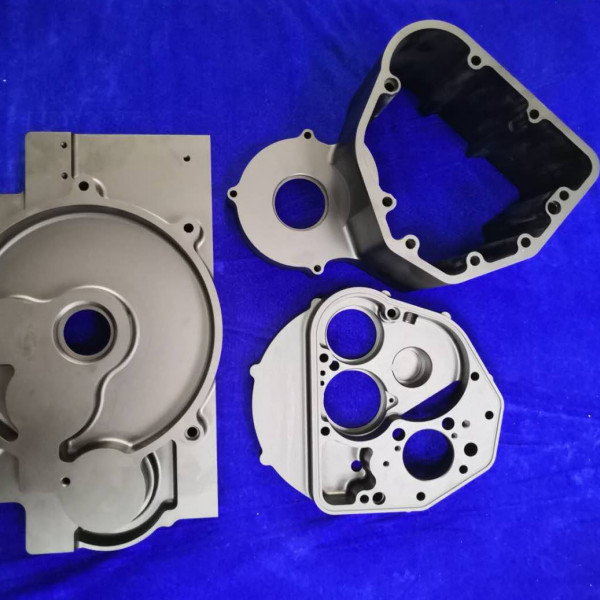

CNC Prototype

A subtractive manufacturing technique called CNC (Computer Numerical Control) prototyping uses great dimensional accuracy to turn CAD models into working prototypes. G-code-driven machining operations are used in CNC prototyping to remove material from solid blocks, such as metal, polymers, or composites. In contrast to additive manufacturing, CNC produces parts with the same material integrity as production-grade parts, tight tolerances (±0.01 mm or greater), and superior surface polish (Such as: Ra < 0.8 μm achievable).

Some of the Key Advantages

- Tolerances: Critical features are precision-machined to within ±0.005 mm.

- Surface Quality: Depending on the toolpath technique, finishes from N6 to N2 can be achieved. Some of the materials are (PEEK, Delrin, ABS), metals (Al6061, SS316L, Ti6Al4V), and composites.

- Structural Integrity: The components maintain their bulk mechanical characteristics, making them perfect for fatigue and stress tests.

- Multi-Axis CNC: 3-, 4-, and 5-axis CNC for freeform surfaces, undercuts, and intricate geometries.

Workflow for CNC Prototypes

CAD modeling: It is the process of creating solid models using CAD software, such as SolidWorks, CATIA, or NX.

CAM Toolpath Generation: CNC toolpaths with optimum feeds, speeds, and cutting techniques are produced with CAM software (such as Mastercam or Fusion 360).

Choosing raw billets and setting up workholding (vises, fixtures, or custom jigs) are two aspects of material stock preparation.

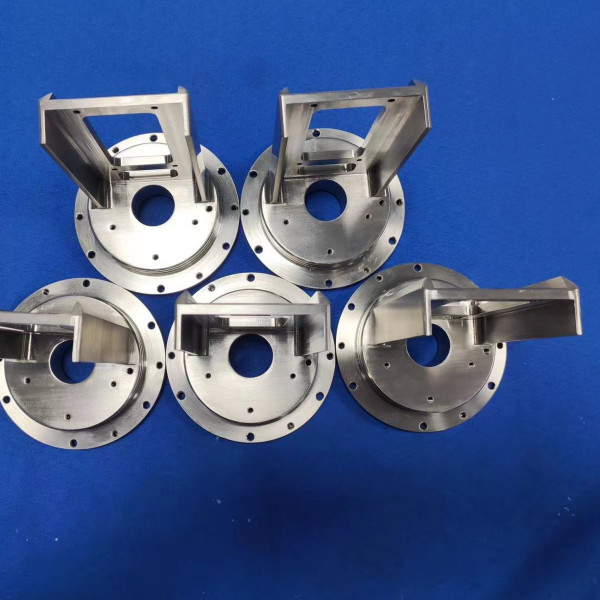

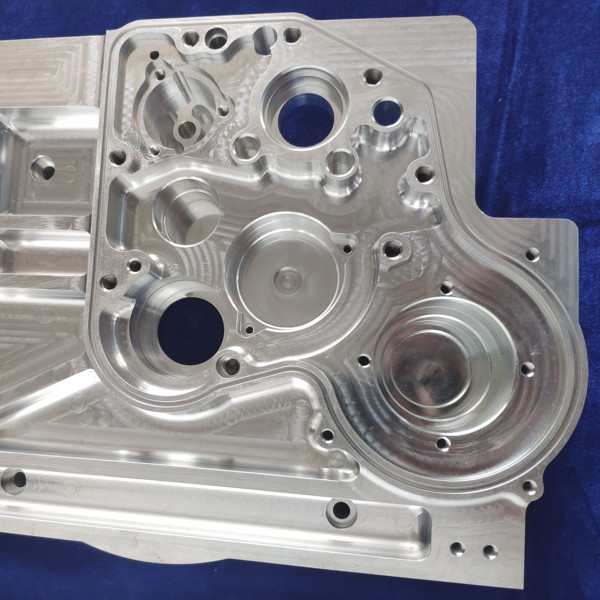

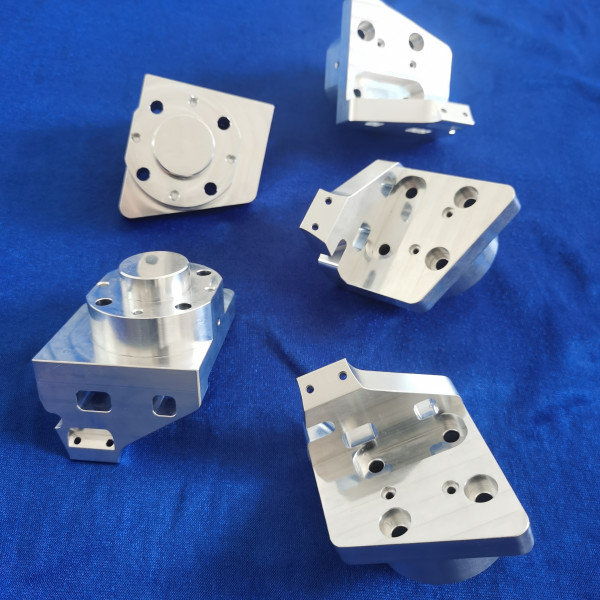

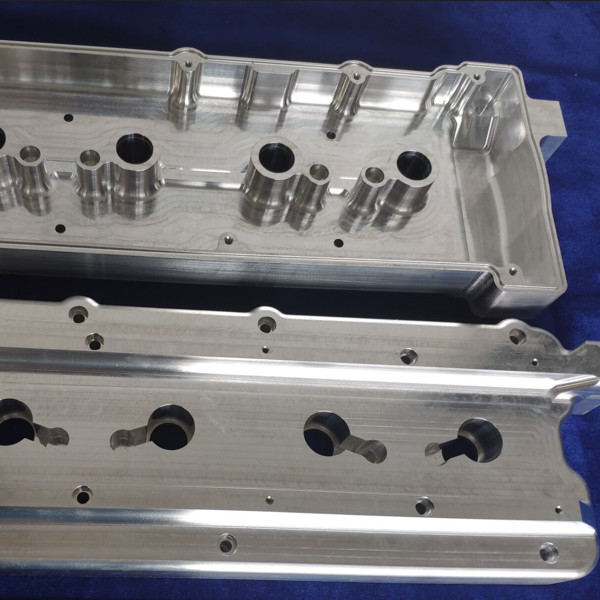

Operations for Machining

- Milling: pocketing, surface polishing, 2D/3D contouring

- Turning: threads, grooved elements, and cylindrical components

- Boring/Drilling: Accurate cavities and holes

- 5-Axis Simultaneous Machining: One setup for complex geometries

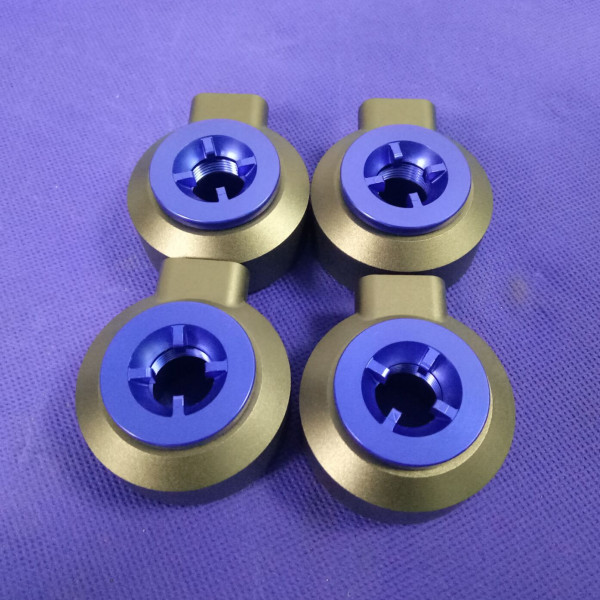

After Processing

- Anodizing, powder coating, bead blasting, polishing, deburring, or plating

- Inspection and Metrology

- Validation of CMM (Coordinate Measuring Machine)

- For GD&T compliance, laser scanning or optical measurement

- Prototype testing includes fit checking, assembly verification, and mechanical load testing.

Common Uses

- Automobile: suspension brackets, gearbox parts, and engine housings

- Aerospace: Fuel system components, structural fittings, and prototype turbine blades

- Medical devices: These include surgical tools, orthopedic implants, and casings.

- Electronics: connection housings, heat sinks, and enclosures

- Industrial machinery: prototypes for bespoke tooling, shafts, and gear housings

CNC Prototyping: Why Use It?

CNC prototype is still superior to additive or molding methods for applications that need production-grade materials, strict tolerance verification, and functional testing under load circumstances. It offers a quick, scalable, and economical way for design engineers to go from digital model to physical validation.