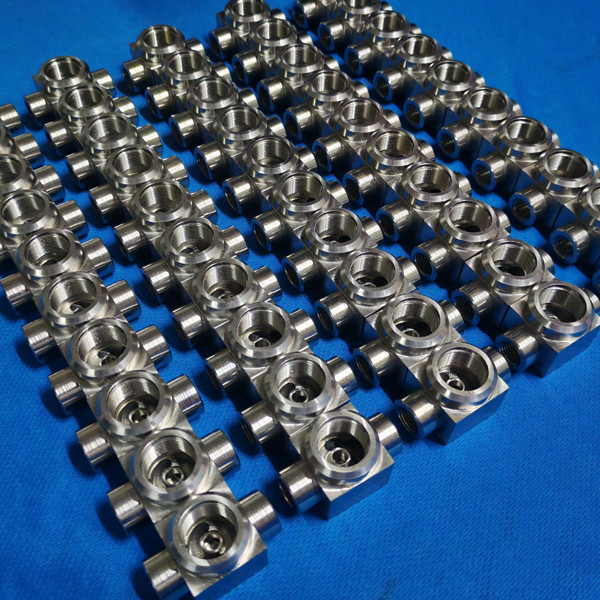

Precision CNC Milling

Businesses want components that are not only dependable but also manufactured with the greatest level of accuracy in the highly competitive manufacturing environment of today. Precision CNC milling is useful in this situation. CNC milling is a crucial machining technique that produces intricate parts with remarkable accuracy and repeatability by utilizing sophisticated computer-controlled systems.

Precision CNC Milling: What Is It?

A revolving cutting tool takes material from a workpiece during the subtractive manufacturing process known as CNC milling in order to mold it into the required shape. Digital design files (CAD/CAM models) are used to train sophisticated equipment used in precision CNC milling, guaranteeing that every cut, slot, and angle adheres to precise specifications. The end product is a faultless part with exacting tolerances that is appropriate for sectors where reliability and quality are crucial.

Advantages of Accurate CNC Milling

- Unmatched Accuracy: Perfect for complicated pieces, it can achieve tolerances as small as microns.

- Consistency: Reliability is ensured across batches by producing parts that are exactly like the original design.

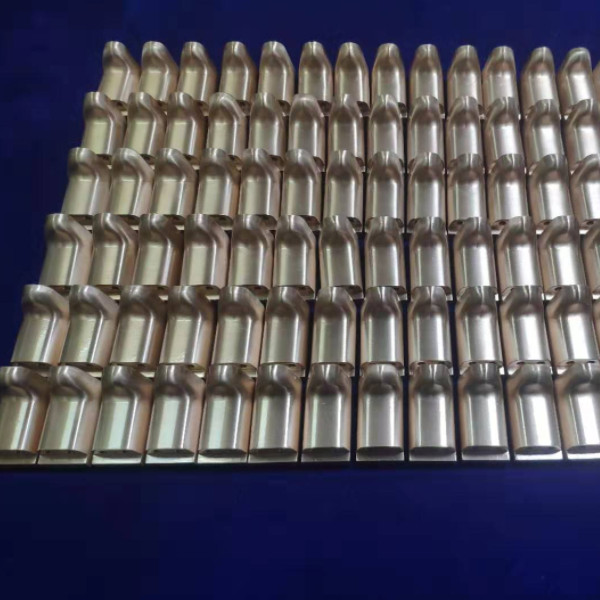

- Material Flexibility: Compatible with composites, polymers, and metals such as titanium, steel, and aluminum.

- Complex Designs: These allow for the production of intricate features, curves, and geometries that are impossible to do with hand machining.

- Efficiency: Automated processes speed up production, cut down on waste, and decrease errors.

Uses in Various Industries

Many industries where accuracy and dependability are crucial use precision CNC milling:

- Aerospace: For lightweight assemblies, structural elements, and turbine blades.

- Medical: To manufacture diagnostic tools, implants, and surgical instruments.

- Automotive: For transmission parts, engine parts, and special prototypes.

- Electronics: Designing circuit board features, housings, and connectors.

- Defense and Industrial: Producing robust, high-performing components for harsh settings.

Comparing Conventional and Precision CNC Milling

CNC milling is mechanized and controlled by computer programs, in contrast to traditional milling, which needs human intervention and is prone to human mistake. Even for complicated projects, this not only increases repeatability but also enables faster turnaround times. CNC milling is more adaptable and economical in the long run since manufacturers can easily transition between prototypes and big production runs.

By fusing speed, accuracy, and flexibility, precision CNC milling has completely changed modern manufacturing. CNC milling guarantees reliable results that are precisely matched to your needs, whether you require a single prototype or thousands of similar parts. Precision CNC milling is the best option for sectors that cannot afford to sacrifice quality.