In the hectic fields of engineering and manufacturing, smart design and overkill are barely separated. Sometimes that threshold is surpassed in the form of over-engineering, a costly and time-consuming mistake that gives a part or product unneeded complexity. Though it may result from excellent intentions, such as increasing dependability or foreseeing edge cases, over-engineering generally does more harm than benefit.

This blog will go over what over-engineering is, why it occurs, how to identify it, and tested methods to prevent it so your next product design is manufacturing-ready, affordable, and efficient.

What is Over-Engineering?

Over-engineering arises, usually leading in extra expenses, manufacturing challenges, or even product failure due to increasing complexity, when a component or good is created to be more durable, complicated, or feature-rich than required for its intended application. It exceeds the functional or safety needs.

Imagine, for instance, building a steel bracket meant to support 100 lbs yet able to withstand 10,000 lbs of stress. However, the part seems “better,” increased strength results in no extra benefit in pragmatic use and wastes money, time, and effort.

Why Does Over-Engineering Happen?

Over-engineering is not a one-sided process; it usually results from several overlapping factors like risk aversion, misinterpretation, and a quest. Let us examine the main factors:

- Fear of Failure

Usually expecting worst-case scenarios, engineers design up too high safety margins. While a margin of safety is essential, pushing beyond reasonable limits can result in overbuilt systems larger, bulkier, and more expensive than required.

- Unclear or Shifting Requirements

When product specifications are ambiguous or undefined, engineers may design for unknowns “just in case.” This inclination to overcompensate sometimes results in inflated designs that aren’t anchored in real demands.

- Perfectionism in Engineering Culture

The desire for excellence sometimes motivates engineers to keep developing a design long after it’s working. This “just one more tweak” approach might introduce features and refinements that contribute little to the fundamental objective but substantially increase complexity and cost.

- Poor Communication Between Teams

Misalignment between design, manufacturing, and business stakeholders can result in mistaken expectations. Engineers might add features or tolerances they believe are essential, even if they weren’t asked for, merely due to unclear direction.

Signs That Your Part Design is Over-Engineered

Recognizing over-engineering early in the design process can save time and dollars. Look for these telling signs:

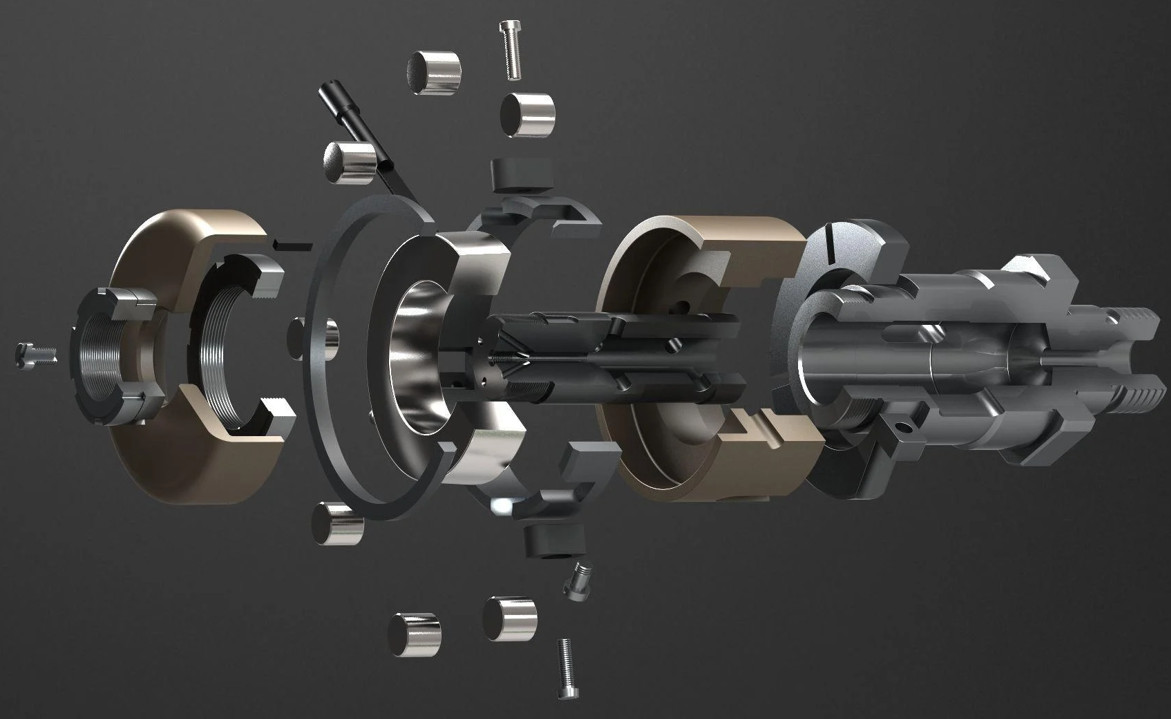

- Excessive Complexity

Does your design contain intricate geometry, too many moving parts, or multi-step assembly processes? If so, it may be more complicated than necessary for the intended function.

- Material Overkill

Are you employing aerospace-grade materials when a regular industrial polymer or metal would suffice? Over-specifying materials is a classic over-engineering trap.

- Unrealistic Tolerances

Tolerances that are overly tight—more exact than required—can substantially increase machining costs and lead to part rejection during quality tests, even if the functionality isn’t affected.

- Long Lead Times

If your product requires highly specialized manufacturing methods or specialist tooling, assess whether the benefits exceed the delay and cost.

- Extra Features That Don’t Add Value

Features that won’t be used in practical applications or offer minimal gains frequently signify that the function has been compromised for form or apparent innovation.

The Hidden Costs of Over-Engineering

Over-engineering often adds hidden costs that harm more than just the technical department. Here’s how it can affect your bottom line and business performance:

- Increased Manufacturing Costs

Over-engineering materials, tight tolerances, and complex geometry contribute to costly tooling, longer machining time, and greater waste.

- Slower Time to Market

Over-engineering designs generally result in more prototyping, more testing, and more time spent resolving minor flaws that wouldn’t exist in a leaner design.

- Difficult Maintenance and Repairs

Complex parts can be tougher to assemble, remove, or replace. If serviceability is important, over-engineering might become a big liability.

- Wasted Engineering Resources

Time spent improving features beyond practical requirements should be better invested in innovating or solving real customer problems.

- Customer Confusion or Frustration

End users may not appreciate or even notice the extra features, especially if they make the product harder to use or more expensive.

How to Avoid Over-Engineering: Practical Strategies

Avoiding over-engineering is about optimizing, not eliminating corners. These tactics help attain the sweet spot between robust and efficient:

- Define Clear Requirements Early

Start by gathering precise specifications: what the part should accomplish, what conditions it will function under, acceptable tolerances, and regulatory or compliance needs. The explicit the standards, the less space there is for speculation.

- Use the 80/20 Rule (Pareto Principle)

Focus on the 20% of design features that give 80% of the functionality or user benefit. This helps avoid spending efforts on polishing features that give minimal practical gain.

- Perform Data-Driven Design Validation

Use technologies like FEA (Finite Element Analysis), temperature analysis, or fatigue simulations to back your design choices. Let evidence, not fear or assumptions, dictate decisions regarding strength and performance.

- Design for Manufacturability (DFM)

Ensure your design suits the production method—whether it’s injection molding, CNC machining, or 3D printing. Work with production teams to find potential for simplification.

- Reuse Proven Components

Avoid reinventing the wheel. Using conventional, off-the-shelf parts where applicable speeds up development, decreases risk, and enhances maintainability.

- Prioritize Function Over Aesthetics

While design appearance matters, utility should be the primary principle. If a sleek design increases manufacturing complexity or unneeded fragility, it’s worth re-evaluating.

- Collaborate Across Departments

Involve manufacturing, procurement, and quality assurance teams early. Cross-functional input can help uncover over-engineering features before they reach production.

Real-World Example: Over-Engineering in Consumer Products

A firm building a fitness tracker insisted on utilizing titanium for the watch shell to “stand out.” Titanium offered scratch resistance and endurance, but came with a heavy price and required skilled machining. Additionally, the waterproofing features were certified at 100 meters, even though customers only intended to wear the tracker in the shower or at the gym.

After user testing, the team concluded most consumers preferred a lightweight design and pricing over engineered materials or diving-level water resistance. By switching to polycarbonate and simplifying the waterproofing, they saved costs by 40% and improved mass production lead time, all without affecting the user experience.

Finding the Balance: Good vs. Great Engineering

The best engineers don’t merely solve problems—they solve them efficiently. Striking a balance between performance and practicality leads to:

- Lower manufacturing costs

- Faster product development

- Simpler maintenance and upgrades

- Higher customer satisfaction

- Greater scalability across product lines

Good engineering meets the need. Great engineering accomplishes the requirement with the least amount of waste.

Conclusion: Keep It Lean, Smart, and Purpose-Driven

Over-engineering is typically the consequence of good intentions, but often leads to needless effects. To avoid it, design with purpose, validate with data, and engage with your entire production environment. Ask yourself at every stage: Does this add actual value? If it doesn’t, you’re likely over-engineering.

In today’s competitive and cost-sensitive industry, lean and efficient design isn’t just good practice—it’s a strategic advantage. Embrace clarity, stay focused on utility, and keep your next part design smart, not overbuilt.