In the highly competitive field of product development, the mere creation of a technically flawless prototype is insufficient. The most successful products of the present day are the result of a profound comprehension of human emotions, requirements, and behaviors. In this blog, we will tell you the fundamental principles of human-centric design, the ways in which it is transforming prototype manufacturing.

What is Human-Centric Design?

Human-centric design, which is also referred to as user-centered design, is a methodology that emphasizes the requirements, desires, and constraints of end-users throughout the entire product development process. It is inclusive, iterative, and empathic, involving direct user feedback, testing, and refinement. HCD reverses the conventional approach of designing a product and subsequently testing it with consumers.

The Importance of Human-Centric Design in Prototype Manufacturing

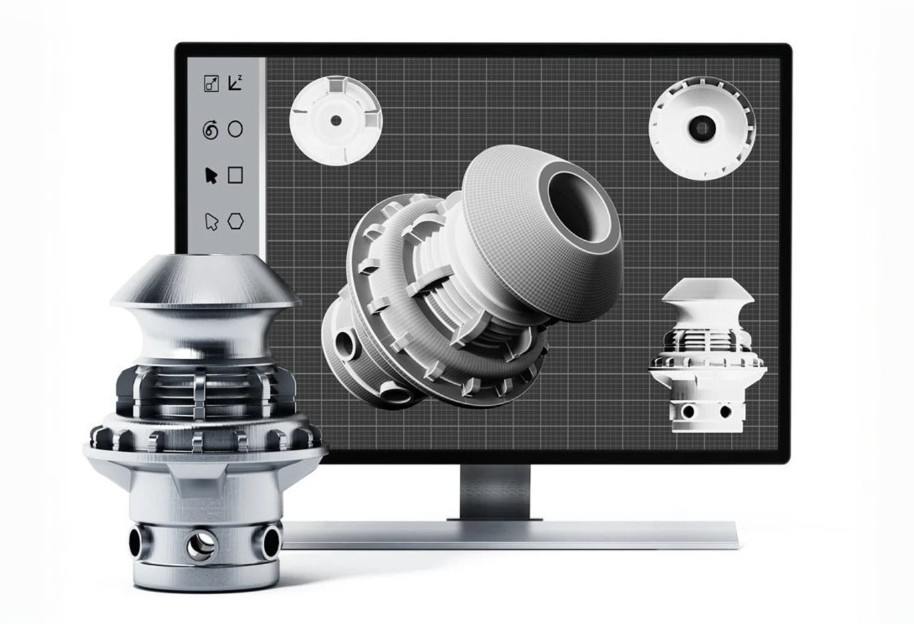

Prototyping is the process by which design concepts are realized in a tangible form. By incorporating HCD into this phase, it is guaranteed that:

- The design assumptions are first verified at an early stage.

- Refinements are influenced by user feedback.

- The likelihood of market rejection is substantially diminished.

Manufacturing technologies such as rapid tooling, CNC machining, and 3D printing have made it easier than ever to construct and iterate on prototypes rapidly.

Key Foundations of Human-Centric Design in Prototyping

- Research Led by Empathy

Engineers, designers, and manufacturers must comprehend the end-user’s life, including their environment, pain points, behaviors, and preferences.

Techniques such as ethnographic investigations, field observations and surveys assist in the development of a real-world context for the product. For example, creating a wearable medical device that is suitable for elderly users necessitates an understanding of emotional comfort levels, visibility limitations, and dexterity challenges.

Empathy guarantees that prototypes are constructed with individuals in mind, rather than solely around concepts.

- Collaboration and Co-Creation

HCD promotes cross-functional collaboration, which encompasses:

- Designers

- Engineers

- UX/UI specialists

- Marketers

- End-users

The identification of friction points and the generation of new ideas are facilitated by the early and active involvement of users in co-creation. Users may test preliminary models, propose modifications, or even emphasize neglected requirements during prototyping.

This inclusive approach guarantees that the prototype develops organically in response to genuine feedback, thereby fostering a more robust product-market fit.

- Feedback Loops and Iterative Testing

The foundation of human-centric prototype manufacturing is iteration. HCD promotes a “build – test – learn – repeat” cycle, rather than attempting to create a flawless prototype in a single step.

This implies that:

- Producing low-fidelity prototypes, including paper models, polystyrene structures, and 3D prints

- Conducting user testing

- Acquiring knowledge from their feedback

- Refinement of the prototype

Each iteration becomes increasingly adept at resolving the issue it is intended to solve. These rapid feedback cycles promote innovation, save time, and reduce waste.

- Inclusivity and Accessibility

Human-centric design is not solely concerned with the average user; it must also consider the diverse range of abilities and requirements of the target demographic.

These considerations result in more inclusive products during prototype development. In order to evaluate usability, inclusive prototyping may entail testing with various user personas, utilizing accessible materials, or simulating disabilities.

- User Delight and Emotional Design

Adoption is not contingent upon functionality alone. Users of the present day anticipate that the products they employ will evoke an emotional response.

This can be accomplished by creating prototypes that:

- Inspire confidence (e.g., financial or medical products)

- Bring delight or simplicity (e.g., home appliances, applications)

- Embrace the aesthetics and values of the brand.

Human-centric prototyping encompasses interactions that emotionally connect with the user, aesthetic detailing, and material selection. During prototype testing, these emotional signals are frequently refined in response to real-time reactions.

Advantages of Human-Centric Design in Prototype Manufacturing

- a) Reduced Time-to-Market

User feedback is integrated into the initial phases of product development, which prevents the need for significant revisions at the end of the process. Iterative prototyping expedites the development of products and reduces the time required for their introduction to the market.

- b) Cost-effectiveness

Preventing costly errors, such as investing in tooling or materials for features that do not add value, is achieved by designing with users from the outset. Testing and enhancing early low-fidelity prototypes is a cost-effective endeavor.

- c) Increased User Satisfaction

Products that are developed with a user-centric approach are more intuitive, functional, and gratifying, which in turn reduces the number of returns, support tickets, and negative reviews.

- d) Competitive Differentiation

Human-centric design offers a strategic advantage in congested markets. Your competitors prioritize specifications, while you prioritize user experience—developing products that are not only indispensable but also beloved.

Examples of Human-Centric Prototyping in Action

Apple prioritized user experience over features in the development of the iPod. The click wheel was optimized for intuitive control through numerous prototype iterations, which were the outcome of ongoing user testing.

Prosthetics for Developing Countries

Engineers who were developing low-cost prosthetics initially investigated the environments in which users operated—including dust, terrain, and sanitation access. Subsequently, they developed solutions that were culturally acceptable, durable, and affordable.

The Future of Human-Centric Design in Manufacturing

HCD: It is being significantly enhanced in prototyping by emerging technologies:

AI & Data Analytics: Intelligently refine prototypes and predict user preferences.

Digital Twins: Prior to the manufacturing of physical prototypes, simulate user interaction with virtual prototypes.

AR/VR Testing: Enable consumers to experience designs in immersive environments, even remotely.

HCD: It also encompasses the environmental impact of sustainable materials. Sustainability is now recognized as an integral component of the human ecosystem by prototypes.

The convergence of technology and empathy is resulting in the development of products that are not only innovative but also responsible and human in every respect.

Conclusion

Human-centric design is not merely a trendy trend; it is a philosophy that is revolutionizing the way we conceive, design, and manufacture. Manufacturers are moving beyond engineering excellence and functionality to create meaningful, pertinent, and delightful products by incorporating human needs into the very DNA of prototypes.