What is Rapid Tooling?

Rapid Tooling is tool that shape products with a certain shape, size and surface accuracy in their specific shape. It is mainly used in large quantities of production, although the mold production and manufacturing costs are relatively high, but due to mass production, so the cost of each product is greatly reduced. According to the functional use can be divided into plastic mold, casting mold, stamping die, forging mold and graphite electrode grinding mold.

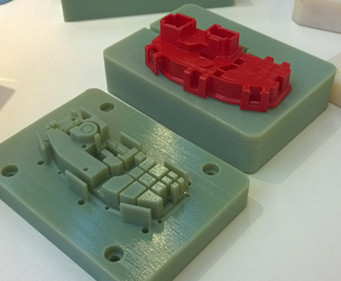

According to the molding material can be divided into simple tooling also known as rapid prototype tooling. We are more familiar with these, so here is not to speak, soft moulding and hard mould technology is different. Soft mold because of its use of soft materials (such as silicone rubber, epoxy resin, etc.) is different from the traditional steel material named after the current soft rapid tooling methods are mainly silicone rubber casting method, metal spraying Method, resin casting method and so on. The number of soft mold products is generally 50 to 5000 pieces, for tens of thousands or even hundreds of thousands of products, still need the traditional steel mold. Hard mold refers to the steel mold, the use of RP prototype production of steel molds are the main investment casting method, ceramic-type precision casting method, EDM and so on.

Based on the rapid prototyping of the rapid mold manufacturing method: first through the RP prototype through the production of the former model, and then through a conversion made of mold cavity, so that you can pour molding products, of course, as we can see after many conversions And the electrode method. Silicone rubber mold rapid tooling process Even if the soft mold is also an indirect mold, silicone rubber mold manufacturing process is a more popular fast mold manufacturing methods. As the silicone rubber mold has a good flexibility and flexibility, can produce complex structure, fine pattern, no draft angle even with the inverted draft angle and deep groove with the parts, the production cycle is short, high quality parts, and thus Much attention. So rapid tooling application is used widely in industry.