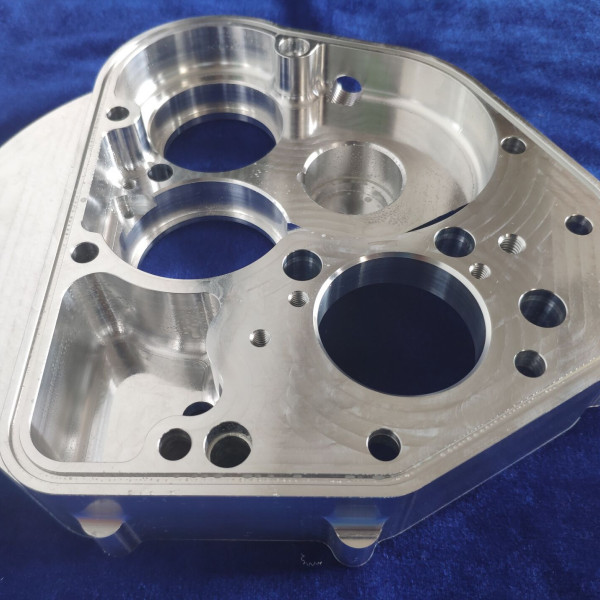

CNC Aluminum Machining

CNC aluminum machining is one of the most popular manufacturing techniques for creating components that are strong, lightweight, and highly precise. Because of its superior strength-to-weight ratio, machinability, and thermal conductivity, aluminum is the material of choice in a variety of industries, including consumer electronics, automotive, aerospace, and medicine.

The Reasons for CNC Machining Aluminum?

- Excellent Machinability: Reduced tool wear while cutting at high speeds.

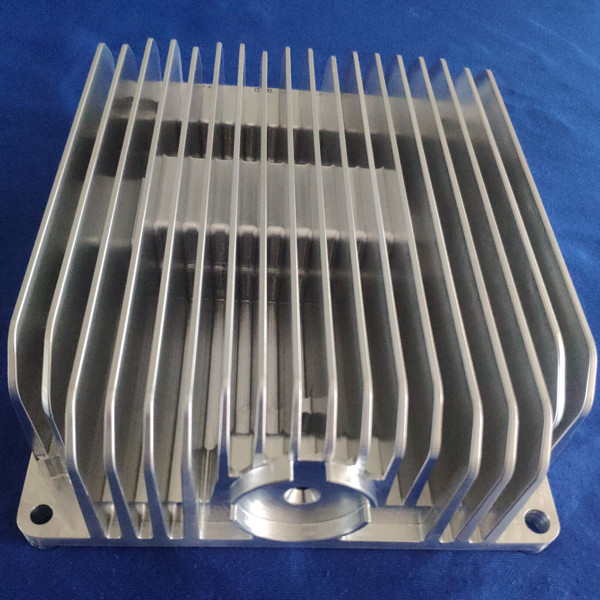

- Electrical and thermal conductivity: make it appropriate for electronic parts, heat sinks, and housings.

- With the right tools, feeds, and speeds, surface finish quality can be achieved with Ra < 0.8 μm.

Common Grades of Machined Aluminum

- 6061: Excellent strength, corrosion resistance, weldability, and general-purpose.

- 6082: Good toughness and machinability for structural applications.

- 5052: Frequently utilized in maritime settings due to its exceptional resistance to corrosion.

Capabilities for CNC Machining Aluminum

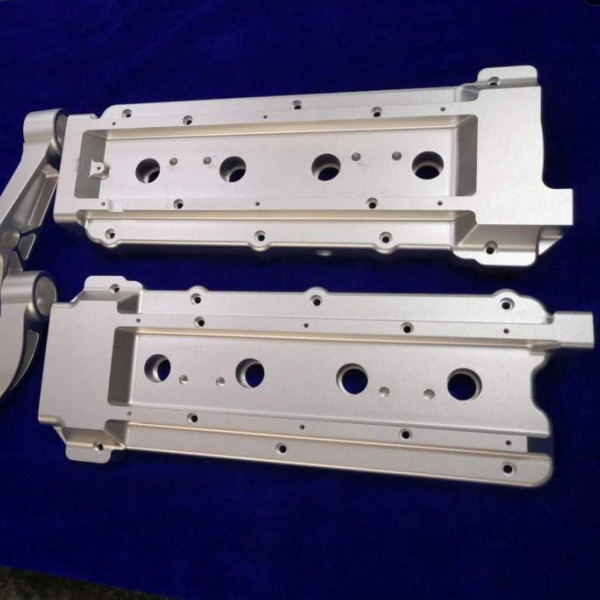

- Three-axis machining: Drilling, contouring, basic profiles, and pockets.

- 5-axis Machining: Low setups, undercuts, and intricate geometries.

- Turning: Accurate cylindrical parts, bores, and threads.

- Increased material removal rate and shorter cycle times are two benefits of high-speed machining (HSM).

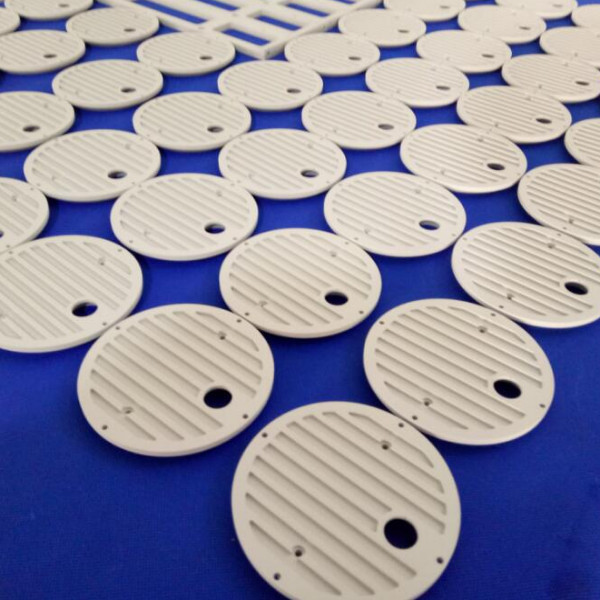

Choices for Surface Finishing

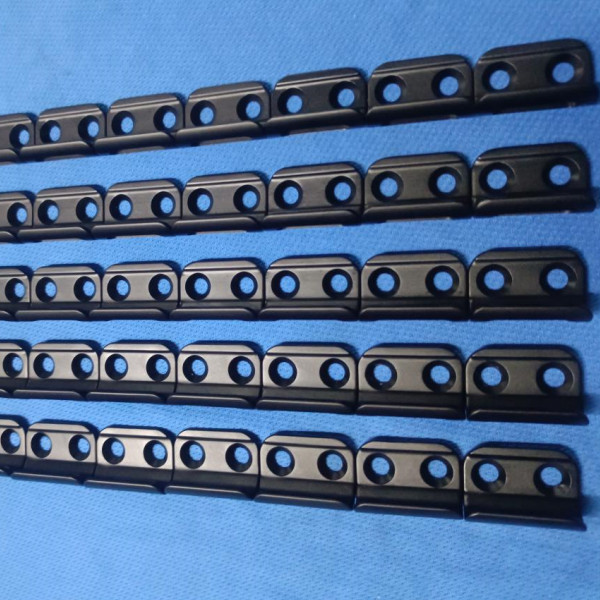

- Improved corrosion resistance and visual appeal are two benefits of anodizing (Type II and III).

- Powder coating is a decorative and long-lasting finish.

- Bead blasting produces a consistent matte appearance.

- Brushing and polishing: both practical and aesthetic enhancements.

- Additional corrosion protection is provided via conversion coating.

Uses for CNC Aluminum Machining

- Avionics enclosures, turbine housings, and structural brackets for the aerospace industry

- Automobile parts: suspension, gearbox housings, and engine components

- Electronics: connections, housings, and heat sinks

- Medical: surgical tools, housings for diagnostic devices

- Specialized equipment, robotics parts, and custom tools

Benefits of CNC Machining Aluminum

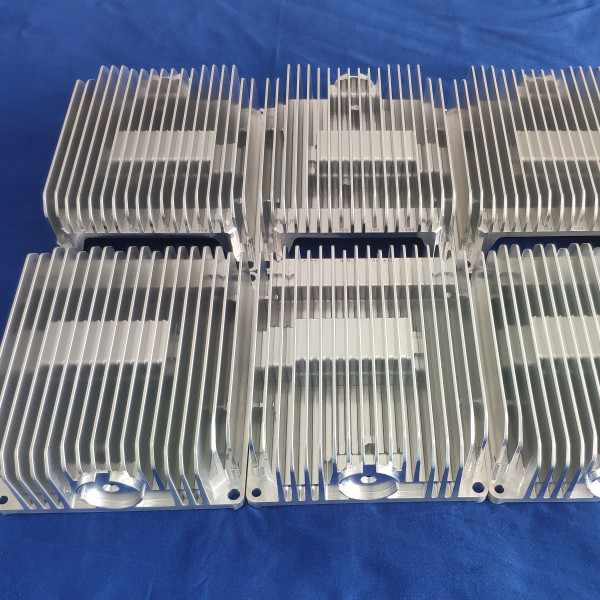

- High precision and reproducibility for both production runs and prototypes.

- High-speed machining techniques allow for quick turnaround.

- Numerous alloys are suited to various mechanical and environmental needs.

- Economical for both large-scale manufacturing and small-scale prototypes.

For sectors that require accuracy, performance, and scalability, CNC aluminum machining is one of the most dependable options because it blends the accuracy of computer-controlled manufacturing with the adaptability of aluminum alloys. Aluminum machining produces lightweight, strong, reasonably priced, and consistently high-quality parts for consumer electronics, medical equipment, and aerospace-grade components at the same time.