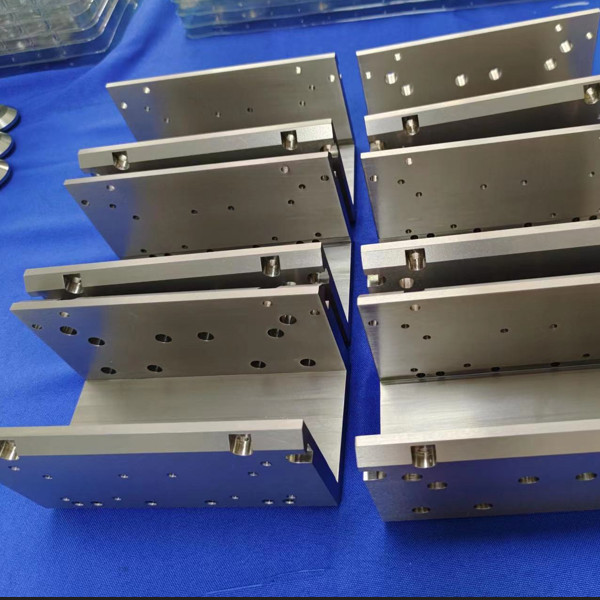

Titanium Machining

One of the most valuable materials in contemporary production is titanium, which is renowned for its remarkable strength-to-weight ratio, resistance to corrosion, and biocompatibility. Because of these qualities, it is perfect for sectors like defense, automotive, medical, and aerospace. However, because of its hardness, low heat conductivity, and propensity to react with cutting tools, titanium is more difficult to machine than other metals. For titanium machining to produce accurate, superior results, specific tools, methods, and knowledge are needed.

The Reasons Titanium Is Hard to Machine

Because titanium does not readily dissipate heat from the cutting zone, it produces a lot of heat during machining, in contrast to steel or aluminum. If not managed properly, this can result in distortion, quick tool wear, and subpar surface finishes.

Methods for Effective Titanium Machining

Manufacturers use sophisticated machining techniques like the following to get over these obstacles:

- High-Performance Cutting Tools: To withstand wear and preserve sharpness, use carbide or coated tools.

- Optimized Feeds and Speeds: To reduce heat accumulation, run at greater feed rates and slower speeds.

- Coolant Techniques: Direct application of high-pressure coolant to the cutting zone to regulate heat.

- Increasing accuracy and permitting complicated geometries in a single setup are two benefits of five-axis CNC machining.

- Toolpath optimization is the process of increasing efficiency while decreasing tool engagement.

Applications

Titanium’s special qualities make it indispensable for sectors where endurance and performance are crucial:

- Aerospace: For structural elements, landing gear, and engine parts that need to be strong without being overly heavy.

- Medical: Because titanium is biocompatible, it can be used to machine implants, surgical tools, and prosthesis.

- Automotive: Used for strong, lightweight parts in racing and high-performance automobiles.

- Defense: Producing military-grade hardware, armor, and weapon components.

Advantages of Accurate Titanium Cutting

When titanium machining is done correctly, it produces:

- Component durability is exceptional.

- Strong and lightweight constructions.

- Superior resistance against heat and corrosion.

- Personalisation for both large-scale manufacturing and prototypes.

Titanium machining creates accurate, dependable, and long-lasting parts with the help of sophisticated CNC machinery, knowledgeable machinists, and specialized tools. Titanium machining is the secret to enabling next-level manufacturing for companies that require strength, effectiveness, and creativity.