For SLA 3d printer, based on the additive manufacturing, is a technique that allows the realization of three-dimensional objects from digital models.

SLA rapid prototyping technology uses epoxy resins that allow the production of highly detailed models even with perfectly transparent resins.

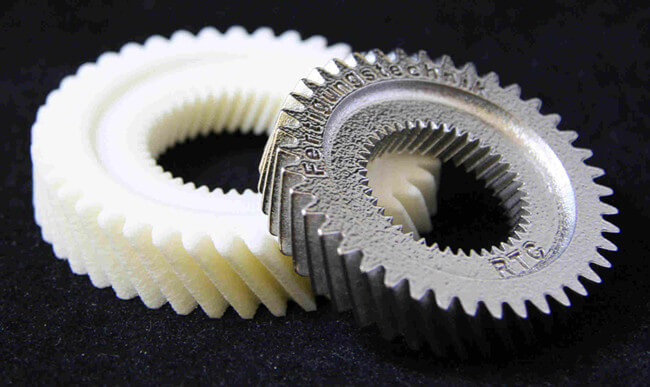

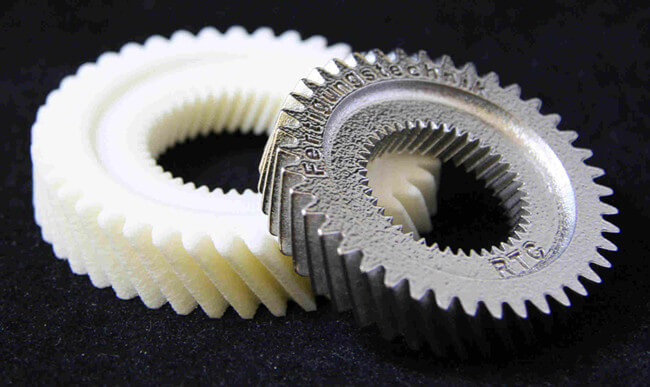

The SLA technology is particularly suited to the production of models by the high surface detail, useful for coupling test, dimensional controls and ergonomic tests. Stereolithography is based on the photopolymerization of a liquid resin, contained in a tank, sensitive to the ultraviolet radiation emitted by a laser source with a system of mirrors. Interaction of laser radiation with the photopolymer triggers a chemical reaction which has as the solidification of the latter effect. Once the process is complete, and with it the model, the build platform emerges from the bath and the excess resin is drained. Finally, the model is placed in a UV oven for a period of final polymerization. The prototype case in stereolithography is undoubtedly those with the best dimensional and surface characteristics. This technology is particularly suitable to obtain optimum levels of detail and for those items where dimensional accuracy and surface is important. The material allows the gumming of the prototypes with hot silicone rubbers (90 degrees) or cold.