The industrial revolution known as computer numerical control (CNC) has made precision, efficiency, and automation possible. Combining superior Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software is crucial for achieving the best outcomes in CNC machining operations. Focusing on their advantages, features, and capabilities, this article will examine the best CAD and CAM software options for CNC production.

SolidWorks

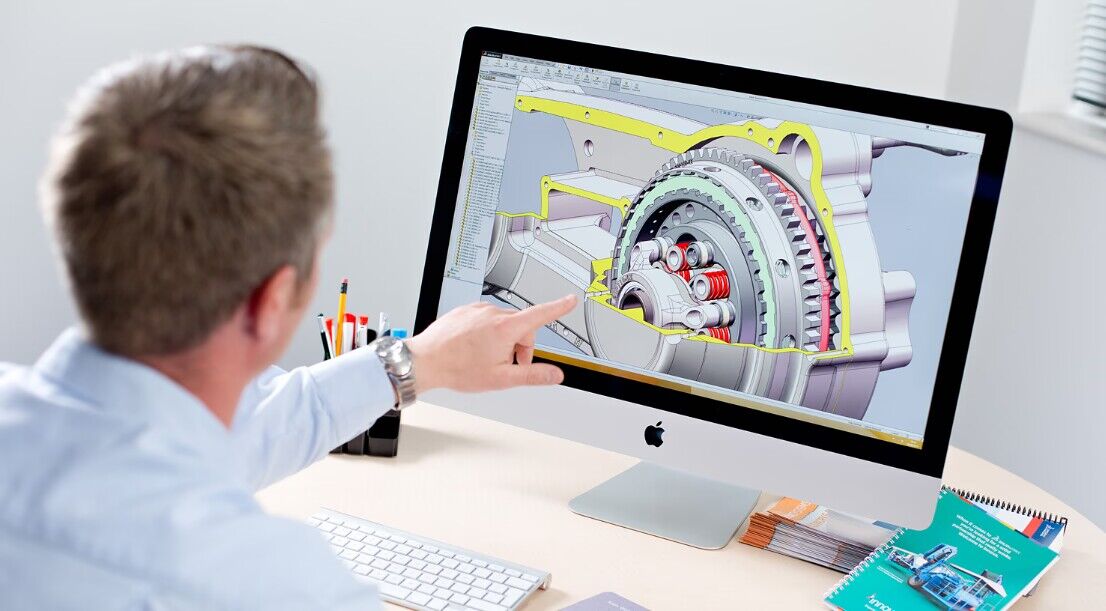

SolidWorks offers 3d solid modeling capabilities and a wide range of simulation tools and is renowned for its user-friendly interface and robust functionality. It is a good option for CNC machining services because of its connection with CAM software. SolidWorks CAM allows 3D models to be seamlessly transferred to CAM, speeding the machining process and guaranteeing effective toolpath creation.

KEY FEATURES:

- Complete simulation and analysis tools; intuitive 3D modeling and assembly features.

- Effortless SolidWorks CAM integration for effective CNC programming.

Fusion 360 by Autodesk

The CAD/CAM platform Fusion 360, created by Autodesk, integrates design, engineering, and production capabilities. Small companies and amateurs use it because of its collaborative capabilities, cloud storage, and parametric solid modeling. Users may generate toolpaths directly from their 3D models using Fusion 360’s integrated CAM capabilities, streamlining the CNC milling process.

KEY FEATURES:

- Surface and solid modeling using parameters.

- Cloud-based data management and collaboration.

- Streamlined CAM integration for CNC programming.

Siemens NX

Powerful CAD/CAM software Siemens NX meets small and big industrial business requirements. It offers cutting-edge production, simulation, and design tools in a single environment. The extensive machining methods, adaptive milling, and multi-axis machining provided by NX’s CAM module make it simple for CNC manufacturers to complete challenging projects.

KEY FEATURES:

- Capabilities for robust modeling and simulation.

- High-speed machining and adaptive milling for the best toolpath generation.

- Combining CAD and CAM on one platform.

Mastercam

Mastercam’s well-known CAM software program is renowned for its dependability and broad range of machining capabilities. It provides various toolpath techniques, such as wire EDM, 2D and 3D milling, and lathe machining. Mastercam is well-liked by CNC makers because of its active community and frequent upgrades.

KEY FEATURES:

- Numerous possibilities for toolpaths for different CNC machining processes.

- Customization of the post-processor for smooth machine communication.

- A vibrant user base for assistance and information exchange.

AutoCAD by Autodesk

One of the most established and extensively used CAD software programs on the market is AutoCAD, which Autodesk also created. Despite being primarily a tool for 2D drawing, it also has 3D modeling capabilities. To produce G-code for CNC machines, AutoCAD is often used in combination with CAM software.

KEY FEATURES:

- Functionalities for efficient 2D drawing and detailing;

- Integration with several CAM programs for CNC manufacturing.

Solid Edge

Siemens created Solid Edge, a feature-rich CAD program that supports parametric and direct modeling. It is a dependable option for CNC production since it provides smooth data flow between design and manufacture. Solid Edge CAM Pro offers sophisticated machining capabilities to improve CNC production processes, such as 2.5 to 5-axis milling and turning.

KEY FEATURES:

- Direct and parametric modeling combined for numerous design possibilities.

- Tools for teamwork to improve communication.

CATIA

CATIA, created by Dassault Systèmes, is a potent and popular CAD program used in the industrial equipment, automotive, and aerospace sectors. It is appropriate for challenging CNC manufacturing tasks since it provides complete design and simulation capabilities. CNC operations may be programmed and carried out effectively thanks to CATIA’s connection with CAM software.

KEY FEATURES:

- Highly developed surface modeling and sheet metal design;

- Powerful simulation tools for kinematics and stress analysis.

- CAM integration for smooth CNC machining.

PTC Creo

PTC Creo, known initially as Pro/ENGINEER, is a feature-rich CAD program that can model directly and parametrically. It is extensively used throughout several sectors, including consumer items, electronics, and the automobile industry. PTC Creo provides dedicated modules for mold design and simulation, improving its usability for CNC production.

KEY FEATURES:

- Direct and parametric modeling for adaptable design processes.

- Simulator modules for mold design for CNC applications.

- Compatibility with CAM applications for CNC machining.

GibbsCAM

The flexible CAM program GibbsCAM is renowned for its user-friendliness and effectiveness in creating toolpaths for CNC machines. It offers milling, turning, and multi-task machining in the 2 to 5-axis range, giving CNC makers a complete solution. The user-friendly design of GibbsCAM and its post-processor library make it a top option for small to medium-sized machining companies.

KEY FEATURES:

- Simple interface for effective CNC programming.

- an extensive post-processor library that enables seamless machine communication.

- Assistance with multi-axis turning and milling operations.

RhinoCAM

MecSoft Corporation created the RhinoCAM plug-in for Rhino, a well-known 3D modeling program. RhinoCAM is appropriate for inexperienced and seasoned CNC makers since it provides various toolpath tactics, such as 2D and 3D milling, engraving, and hole-making. Its interaction with Rhino makes the journey from design to CNC machining easier.

KEY FEATURES:

- A wide range of toolpath possibilities for different CNC operations.

- Rhino integration for effective CAD to CAM workflow.

- An affordable option for amateurs and small enterprises.

Conclusion

For custom CNC machining parts to be successful, it is essential to integrate high-quality CAD and CAM software successfully. SolidWorks, Autodesk Fusion 360, Siemens NX, Mastercam, Autodesk AutoCAD, Solid Edge, CATIA, PTC Creo, GibbsCAM, and RhinoCAM, are some of the best software solutions for CNC manufacturers. Other popular options include Autodesk AutoCAD. Every piece of software has a unique set of benefits. It may be adapted to meet the specifications of various business sectors, kinds of projects, and budgetary limitations. By using the capabilities of these advanced CAD and CAM tools, CNC manufacturers have the potential to boost their productivity, improve their accuracy, and preserve their competitiveness in the manufacturing industry, which is undergoing fast change. Regardless of the size of your organization, there is a CAD/CAM software solution that will allow you to develop your CNC manufacturing processes and open up new options in design and production.