Plastic prototype manufacturing is undoubtedly a very important issue today, and we can see how this material has managed to meet the characteristics that so many manufacturers have desired for the creation of all their products, and even has given the opportunity to be very creative with the ideas they have for their future.

The plastic parts were governed by characteristics that were a bit rigorous, so they did not help the evolution of the objects .Previously, creating plastic parts was a somewhat difficult job to carry out, since some methods had to be used that, although similar to the current ones, were never entirely effective, since they did not give the necessary freedom to make the creation of Prototype plastic parts more evolved than those that already existed.

This led to Plastic prototype manufacturing being forced to incorporate as many processes that gave great creative freedom, not only for manufacturers, but also for all those who perhaps thought of bringing to market products that could, with their simplicity, cover one or more various needs that were had at the time.

The need for custom plastic parts grew, and with it came multiple ideas and solutions that would stick around for the future .This is how the need for the creation of Custom plastic parts arose, and the solutions regarding this would be accompanied by other solutions to problems that they did not even know existed at that time.

The solutions were varied, and although they directed their attention to quite specific problems, in the end, the results also showed solutions for many other problems that would arise soon .For example, today we can clearly see the existence of Low-Volume Plastic Parts, which under no ancient method could have been manufactured, since the density that was required to fill some molds, was really high for what was required. This was one of the reasons why the way in which the Plastic rapid prototyping and also the normal ones were manufactured diversified.

While it is true that there are so many ways to mold this material to create various parts, only a few stand out as the best Prototype plastic parts manufacturing options.

Prototype & Plastic Mold:

Molding was always one of the ancient ways of achieving the manufacture of plastic parts, that is to say, the material was only poured into a rigid mold, and once it passed to a solid state, it was removed and imperfections began to be eliminated.

The relationship between Prototype & Plastic Mold today is much simpler, especially when it comes to plastic injection molding. This method allows the creation of parts to be simple, precise, without this material being lost in large quantities.

It also turned out to be the perfect solution for the creation of Low-Volume Plastic Parts since although the plastic had to enter a mold, it would have an exact measurement of the part, especially if it was very small and required little material for its manufacturing.

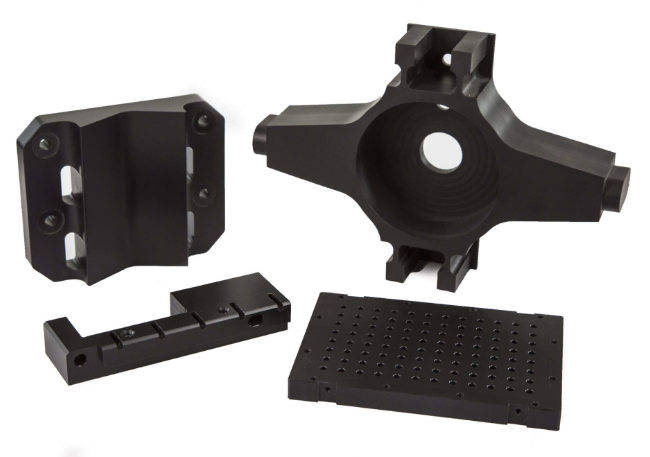

CNC plastic prototype :

This is also the ideal method to create Low-Volume Plastic Parts or Custom plastic parts, and it is evident that through this accelerated and successful process, the parts can achieve quite unthinkable characteristics, such as the transparency of a plastic .Through this strategy, pieces can be created that do not require a large amount of plastic to achieve their shape. It may also be able to recreate any image or requirement that is input to the main machine, which executes these commands with precision.

3D printing is also a fairly complete process for the creation of plastic parts of any characteristic, we can say that it is also a great helper to be able to Custom plastic parts thanks to its characteristics .Through 3D printing, a machine is capable of recreating even the most complex plastic parts that exist, with a precise volume and high quality.

Whichever method manufacturers choose, they can be sure that in any of these three ways, they will be able to find the ideal one for the creation of all their parts and products, because at present it is not difficult to comply with even the most complex idea and demanding to be related to Prototype plastic parts.