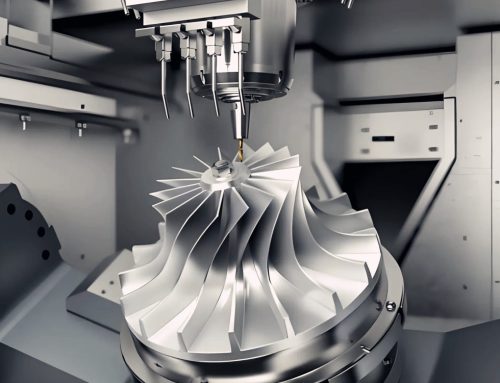

CNC manufacturing services has made material creation feasible with previously unattainable precision and complexity. Acrylic and polycarbonate are popular CNC machining thermoplastics. Both materials have unique and versatile properties. Acrylic and polycarbonate are used in CNC manufacturing in different ways. This study examines their pros and cons.

Overview of Acrylic and Polycarbonate

Acrylic

Acrylic, or polymethyl methacrylate (PMMA), is a lightweight, shatter-resistant glass alternative. Acrylic’s transparency, UV resistance, and wearability make it popular in aesthetic and functional applications. Acrylic is versatile and utilized in many industries; it comes in numerous colors and finishes. So it’s widely used in life everywhere.

Polycarbonate

Polycarbonate (PC) is another thermoplastic polymer with excellent heat, impact, and durability. It is stronger than acrylic and is used for impact-resistant applications. Polycarbonate is transparent and available in sheets and molds. Compared to Acrylic, it’s stronger, not to be easy broken up.

Properties of Acrylic and Polycarbonate

Transparency and Aesthetic Quality

- Acrylic’s optical clarity is exceptional; its light transmittance ranges from 92% to For uses such as exhibition cases, signs, and lighting installations where visibility and visual appeal are absolutely vital, this quality makes it a great option.

- Polycarbonate has a somewhat lower light transmittance than acrylic, even if it is still very clear. Still, it comes in many textures and finishes, giving designers plenty of choices for particular uses.

Impact Resistance

- Polycarbonate is almost indestructible under pressure as it is well-known for its great impact resistance. This quality makes it widely utilized in safety and security-related products like riot shields, eyeglasses, and protective barriers.

- Acrylic is less fit for uses requiring great durability as it is more likely to break and shatter under high-impact circumstances.

Chemical Resistance

- Acrylic resists many chemicals quite well, although powerful acids and solvents may affect it. Acrylic should not be used in surroundings where it might come into touch with strong chemicals.

- Although polycarbonate is sensitive to certain solvents and some chemicals, it has higher resistance to many others. The particular chemical exposure anticipated in the application might determine which of the two materials to choose.

Heat Resistance

- With a heat distortion temperature of around 130°C (266°F), polycarbonate can resist greater temperatures and maintain structural integrity in high-heat surroundings. This qualifies polycarbonate for use in heat-exposed electrical housings and automobile components.

- Acrylic’s lower heat distortion temperature—about 80°C (176°F—limits its employment in high-heat operations. High temperatures cause it to bend or distort.

Weight

- Though acrylic is usually lighter than polycarbonate, both materials are lighter than glass; this may be helpful in uses where weight is a factor, such as portable displays or lightweight buildings.

CNC Manufacturing Process for Acrylic and Polycarbonate

With CNC machining, computer-operated machines precisely remove material from a workpiece. Although both acrylic and polycarbonate may be machined successfully using different methods, considerations vary between the two materials.

- Machining Techniques

Cutting and Milling

Standard milling and cutting equipment lets one machine produce both acrylic and polycarbonate. Nevertheless, the equipment and cutting rates can require change depending on their different qualities. Although acrylic may be machined faster, it’s important to utilize sharp tools to guarantee neat edges and stop melting. To prevent cracking and overheating, polycarbonate could, on the other hand, need slower speeds.

Drilling

Particularly near edges, drilling holes in acrylic may cause chipping and breaking. Specialist drill bits made of plastics can be used to help reduce this problem. Usually able to withstand conventional drill bits, polycarbonate should be watched for heat generation, which might cause distortion.

Routing

One may route both materials to produce complex forms and patterns. Because acrylic generally results in better edges, it is appropriate for use when calling for a premium finish. Rougher edges from polycarbonate routing might call for further polishing work.

Laser Cutting

For laser cutting, acrylic is well suited as it generates polished, crisp edges without additional polishing required. Laser cutting polycarbonate may also be done, but it may need more power and operators have to be careful of fumes produced during the operation.

- Finishing Techniques

Edge Finishing

Polishing acrylic will help it to have a shiny, smooth surface, therefore improving its visual attractiveness. Although more difficult to polish, polycarbonate’s look and durability may be enhanced via sanding or coating processes.

Surface Treatments

Surface treatments help both materials become more resistant to UV damage, chemical exposure, and scratches. For polycarbonate, for example, coatings help to increase its service life and scratch resistance.

Advantages and Disadvantages

Acrylic

Advantages

- Excellent optical clarity yields vivid color and brightness.

- Lighter than polycarbonate, therefore perfect for lightweight uses.

- Simpler to shape and produce, enabling detailed designs.

Disadvantages

- Less impact-resistant than polycarbonate, so it breaks easily.

- They are more likely to scratch and chip, so they are handling calls with extra care.

- Under great heat, it may twist or distort.

Polycarbonate

Advantages

- Excellent durability and impact resistance, which qualifies for use in safety.

- Increased heat resistance preserves performance at higher temperatures.

- More chemical resistance than from acrylic.

Disadvantages

- Possibly a factor for certain uses as optical clarity is somewhat less than that of acrylic.

- Usually more costly than acrylic, so project budgets may suffer.

- It may scratch unless covered with protective layers.

Applications of Acrylic and Polycarbonate

Usually, the particular needs of the application will determine which acrylic and polycarbonate are more suitable. Each substance has many typical applications, as follows:

Acrylic Applications

- Acrylic’s clarity and adaptability make it extensively utilized in lighted signs, shop displays, and informative signage.

- Lighting Fixtures: Acrylic is a common option for light covers, lenses, and ornamental lighting components because of its great light transmission.

- Aquariums: Acrylic’s lightweight and transparent character makes it perfect for building aquariums, as it offers a clear view and is less prone to breakage than glass.

- Acrylic provides a clear vision and guarantees safety when used in sneeze guards and protective barriers in different environments.

Polycarbonate Applications

- Polycarbonate’s impact resistance makes it widely utilized in creating protective helmets, face shields, and safety eyewear.

- Automotive Components: Where durability and heat resistance are critical, polycarbonate is often found in headlamps, lenses, windows, and dashboard components.

- Building Materials: Polycarbonate is used in greenhouses, skylights, and roofing panels where its UV resistance and strength improve lifetime and performance.

- Polycarbonate is utilized in electrical housings and components because of its great insulating qualities and resistance to heat, therefore guaranteeing dependability and safety.

Environmental Considerations

Since polycarbonate and acrylic both come from petroleum-based sources, questions about their environmental effects abound. Both materials, however, with considerable variations, may be recycled.

Acrylic Recycling

By mechanical means, acrylic may be recycled; it is crushed into grains and remolded into new goods. Still, the rates of recycling acrylic are usually smaller than those of other materials.

Polycarbonate Recycling

Furthermore, polycarbonate is recyclable, and its qualities may be maintained throughout the recycling process, thus enabling the production of new goods without appreciable loss of quality. Certain manufacturers have developed techniques for efficiently reclaiming and recycling polycarbonate.

Conclusion

Acrylic and polycarbonate are CNC-friendly materials with pros and cons. Acrylic is selected for its optical clarity and aesthetic appeal, whereas polycarbonate is chosen for its toughness and impact resistance. Manufacturers must grasp material attributes, machining features, and applications before making project-related decisions.

As CNC technology advances, more inventive concepts for handling these materials will emerge across many industries. Polycarbonate for strength and acrylic for beauty are significant materials for modern manufacturing and design because they provide numerous chances for innovation and usefulness.