Vertical (three-axis) The most effective machining surface is only the top of the workpiece, horizontal machining center with rotary table, can only complete the workpiece four-sided processing. At present, high-end processing center is moving in the direction of the five-axis control, the workpiece can be completed once the five-dimensional processing of the five. Such as the configuration of CNC Machining Center five-axis linkage of the high-end CNC system, but also on the complex spatial surface of high-precision processing.

Vertical five-axis machining center

There are two ways to rotate the axis of this type of machining center, one is the rotary table of the table. The table set on the bed can be rotated around the X axis, defined as the A-axis, A-axis general operating range +30 degrees to -120 degrees. The middle of the table also has a turntable, in the illustrated position around the Z axis rotation, defined as the C axis, C axis are 360 degrees rotation. This combination of the A-axis and the C-axis, the workpiece fixed to the table in addition to the bottom surface, the remaining five faces can be processed by the vertical spindle. A axis and C axis minimum grading value is generally 0.001 degrees, so that the workpiece can be subdivided into any angle, the processing of inclined, inclined holes and so on. A-axis and C-axis, such as with the XYZ three linear axis to achieve linkage, you can process a complex space surface, of course, this requires high-end CNC system, servo system and software support. The advantage of this arrangement is that the spindle structure is relatively simple, the spindle stiffness is very good, the manufacturing cost is relatively low. But the general table can not be designed too much load is also smaller, especially when the A-axis rotation is greater than or equal to 90 degrees, the workpiece cutting will bring a lot of load carrying torque table.

The other is to rely on vertical spindle head rotation (Figure). The front of the spindle is a rotary head, can be around the Z axis 360 degrees, as the C axis, rotary head also can rotate around the X axis of the A axis, generally up to ± 90 degrees or more, to achieve the same function. The advantage of this setting is that the spindle machining is very flexible, the table can also be designed very large, the aircraft large body, a huge engine shell can be processed in such processing center. This design also has a great advantage: we use the spherical surface processing, when the center line perpendicular to the processing surface, because the spherical milling machine vertex line speed is zero, the top of the workpiece surface quality will be poor, the use of spindle rotation Of the design, so that the spindle relative to the workpiece through an angle, so that the spherical cutter to avoid the vertex cutting, to ensure a certain line speed, can improve the quality of surface processing. This structure is very welcome by high-precision surface processing, which is difficult to do the rotary table processing center. In order to achieve high precision rotary, high-end rotary shaft is also equipped with a circular grating feedback, sub-degree accuracy in a few seconds or less, of course, the spindle of the rotary structure is more complex, manufacturing costs are higher. It ensures CNC Machining Parts better.

Spindle rotation of the vertical five-axis machining center

Vertical machining center of the spindle gravity down, bearing high-speed operation of the radial force is equal, good rotation characteristics, it can improve the speed, the general high-speed up to 1,2000r / min or more, the practical maximum speed has reached 4,0000 turn. Spindle system is equipped with a circulating cooling device, circulating cooling oil to take away the heat generated by high-speed rotation, through the refrigerator down to the appropriate temperature, and then back to the spindle system. X, Y, Z three linear axis can also be used linear encoder feedback, two-way positioning accuracy within the micron level. As the rapid feed to 40 ~ 60m / min or more, X, Y, Z axis of the ball screw mostly central cooling, with the spindle system, by the cooling of the circulating oil flow through the center of the ball screw, take away the heat.

Horizontal five-axis machining center

There are two ways of turning the rotary shaft of this type of machining, one is the horizontal spindle swing as a rotary shaft, plus a rotary shaft of the table, to achieve five-axis linkage processing. This arrangement is simple and flexible, such as the need for spindle vertical and horizontal conversion, the table only needs to index positioning, you can simply configure the vertical and horizontal conversion of the three-axis machining center. By the spindle vertical and horizontal conversion with the table division, the workpiece to achieve pentahedral processing, manufacturing costs, and very practical. Can also set the CNC axis of the table, the minimum scale value of 0.001 degrees, but not for linkage, as the vertical and horizontal conversion of the four-axis machining center, to adapt to different processing requirements, the price is very competitive. This type of CNC Machining Services will be more and more popular.

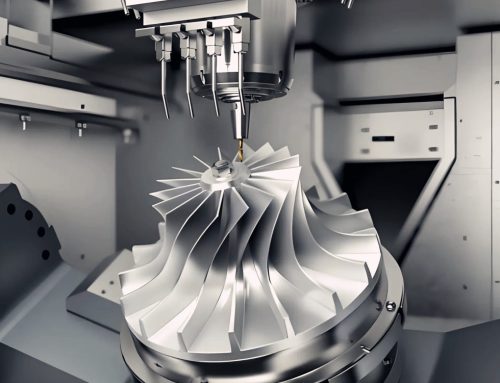

The other for the traditional table rotary shaft, set in the bed of the table A axis of the general working range +20 degrees to -100 degrees. The middle of the table also has a rotary table B-axis, B-axis can be two-way 360 degrees rotation. This horizontal five-axis machining center linkage characteristics than the first way is good, commonly used in processing large impeller complex surface. Rotary axis can also be configured with circular grating feedback, indexing accuracy of a few seconds, of course, this rotary shaft structure is more complex, the price is expensive.