No matter the size of a business, rapid prototypes are important and necessary because they drive productive conversations about if a design needs rework or will function as intended. Fewer iterations are needed to take the design from concept to creation and delivery, and the manufacturer is confident that their product will meet customer requirements.

Now when you view the social medias through by Facebook. Twitter. Linkedin to check out rapid prototyping methods, you will be seeing the most popular methods in western countries is 3D printing. But in China, just the opposite. Most manufacturers use CNC technology. Choosing the right popular rapid prototyping methods depends on what type of product or object you have designed. Which technique will best suit the material, size, complexity, finished? It is important to understand the advantages and disadvantages of each technique to determine which one to choose.

For example:

1) SLA has accuracy, detail and a presence in industry. However, it is limited in available materials, it’s resin, needs supports, and needs to be polished after production.

1) SLA has accuracy, detail and a presence in industry. However, it is limited in available materials, it’s resin, needs supports, and needs to be polished after production.

2) SLS, on the other hand, doesn’t require any post curing, has limited need for support structures, and a larger range of material choices. In most cases, Nylon is the most used. It does require some finishing and changing from different materials can be difficult compared to other rapid prototype techniques.

3) 3D printing can print a lot of plastics and metals, even rubber. Especially for the complex structure part, it has a big advantage. But for some special metal and plastic, it’s unavailable yet.

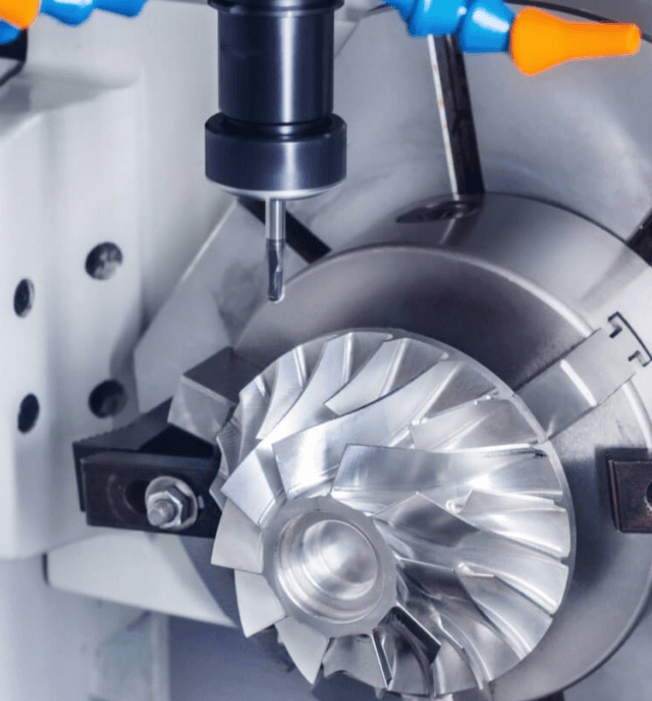

4) CNC machining & Turning has been using widely for Prototype Parts Manufacturing and mass production. In China, in fact, CNC Prototype is more effective than 3D printing, such as: For Titanium Part, if you make it in 3D printing, the surface is very tough. And the printed material is limited too. The production cost will be more with low volume production. But making it in CNC, the surface of part is smooth, it can be polished and ground as well, in the meantime, it suits a series of volume production.

Choosing one of the most popular rapid prototyping methods is easy when you learn the process, advantages and disadvantages of each technique and compare them to the requirements of your product design, budget, materials, sizes and finished are the blueprints to determining which of the most popular rapid prototyping methods is best for you.