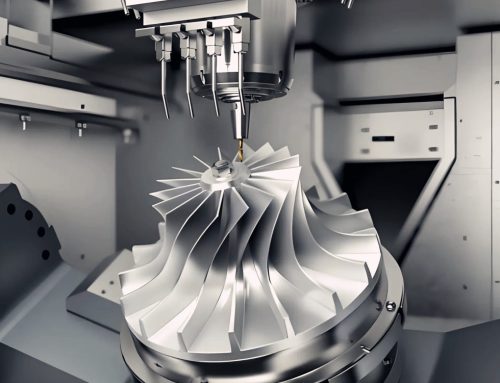

One often-used manufacturing technique that precisely forms materials into parts and components is CNC machining. Machining efficiency, product durability, and cost are largely influenced by the material used. Hard and soft metals are generally used to describe the most commonly used metals in CNC machining. Choosing the suitable material for a specific project depends on being aware of its characteristics, uses, and machining difficulties.

Hard Metals in CNC Machining

Properties of Hard Metals

Hard metals are characterized by their considerable tensile strength, durability, and resistance to wear and corrosion. These metals are ideal for heavy-duty applications, as their melting points are typically high, and they can withstand hostile conditions. Common hard metals are those of which:

Stainless steel

Medical, aeronautical, and industrial uses for stainless steel—known for its strength and corrosion resistance—also find a place here.

Titanium

Commonly used in aircraft, medical implants, and the maritime sector, titanium is lightweight yet robust and corrosion-resistant.

Tool Steel

Tool steel, used for drilling and cutting instruments, maintains toughness even at high temperatures.

Tungsten

Tungsten is one of the toughest metals; it is used in military and industrial items that require exceptional longevity.

Machining Challenges of Hard Metals

Due to their high hardness, resistance to deformation, and wear resistance, hard metals pose significant challenges during CNC machining, yet they provide excellent strength and endurance. These elements make them more difficult to cut, which increases machining time and tool wear, and requires specific cutting equipment and procedures.

High Tool Wear

Machining hard metals accelerates tool wear due to their hardness, thereby increasing the frequency of tool changes.

Slow Machining Speed

Lower cutting rates and feeds are required for hard metals to prevent excessive heat generation and extend tool lifetime.

Heat Generation

High temperatures generated by the machining operation could cause material deformation and damage to cutting tools.

Higher Costs

Hard metals’ tenacity means that they may require specific cutting tools and coatings, which increases manufacturing costs.

Best Practices for Machining Hard Metals

Examining the following recommended practices can help you effectively machine hard metals:

Use Carbide or Diamond-Coated Tools

These tools keep sharpness longer and resist the strain of cutting strong metals.

Simplify Cutting Feeds and Speeds

Stable feeds and slower rates help reduce tool wear and overheating.

Employ Coolants and Lubricants

Using cutting fluids increases surface smoothness and helps to prevent heat buildup.

Check Appropriate Machine Rigidity

Precise machining of hard metals depends on a sturdy and vibration-free CNC configuration.

Soft Metals in CNC Machining

Properties of Soft Metals

Soft metals are easier to work with due to their low hardness, suppleness, and high thermal and electrical conductivity. These metals are ideal for applications requiring minimal weight and flexibility. Among the common soft metals are:

Aluminum

Aluminium, lightweight and corrosion-resistant, finds extensive use in consumer electronics, automotive, and aerospace technologies.

Brass

Often used in plumbing and decoration, a copper-zinc alloy is well-known for its machinability and corrosion resistance.

Copper

Copper is necessary in heat exchangers and electrical components due to its high thermal and electrical conductivity.

Lead

a soft yet dense metal used in batteries and radiation shielding.

Machining Advantages of Soft Metals

In CNC machining, soft metals offer several advantages that make them a popular choice for applications requiring high-speed production, intricate detailing, and cost efficiency. Their lesser hardness allows cutting processes to proceed more smoothly, thereby relieving tool tension and enabling quicker turn-around times.

Faster Machining Speeds

Their low hardness lowers machining time and allows fast cutting.

Lower Tool Wear

Since they are less abrasive, cutting tools last longer when machining soft metals.

Better Surface Finishes

With little post-processing, soft metals provide more seamless surfaces.

Cost-Effectiveness

These metals are usually more reasonably priced and require less energy-intensive processing techniques.

Challenges in Machining Soft Metals

Machining soft metals presents various difficulties, despite their benefits, which are mostly related to their ductility, tendency to adhere to cutting tools, and sensitivity to deformation under high-speed machining conditions. Correct machining techniques and handling methods help reduce these problems and ensure optimal performance.

Galling and burring

Because soft metals attach to cutting instruments, material accumulates, and jagged edges result.

Deformation

Heat or excessive cutting power may distort soft metals, thereby affecting dimensional accuracy.

Chip Control Issues

Long, stringy chips created by certain soft metals may clog tools and reduce machining performance.

Best Practices for Machining Soft Metals

Use these rules to maximise CNC machining for soft metal work:

Use Sharp Cutting Tools

Sharp tools stop galling and reduce material adherence.

Increase Cutting Speeds

Faster speeds lower cutting forces and increase efficiency.

Apply Proper Chip Control Strategies

Perfect tool paths and chip breakers help control chip generation.

Monitor Coolant Usage

Using coolant correctly enhances surface quality and helps prevent overheating.

Comparing Hard Metals and Soft Metals in CNC Machining

Comparing the mechanical qualities, machinability, cost-effectiveness, and general performance of different metals can help one choose the most suitable metal for CNC machining. Both soft and hard metals have unique benefits and drawbacks, which qualify them for varied uses. This chart provides a straightforward comparison to help producers select the appropriate material based on their project requirements.

| Feature | Hard Metals | Soft Metals |

| Hardness | High | Low |

| Machinability | Difficult | Easy |

| Tool Wear | High | Low |

| Cutting Speed | Slow | Fast |

| Heat Generation | High | Low |

| Cost | Expensive | Affordable |

| Applications | Aerospace, Medical, Defense | Automotive, Electronics, Decorative |

Choosing the Right Metal for CNC Machining

The suitable metal choice for CNC machining will rely on material qualities, machining efficiency, cost, and end-use applications, among other factors. Engineers and manufacturers have to assess several factors to decide which is the greatest fit for a certain project:

Application Requirements

Consider factors such as strength, corrosion resistance, weight, and thermal conductivity.

Machining Constraints

Account for tool wear, machining time, and cost efficiency.

Surface Finish Needs

Determine whether the finished item requires a rough or smooth finish.

Production Volume

Easier-to-machine soft metals may help facilitate high-volume manufacturing.

Conclusion

Both soft and hard metals have value in CNC machining, with each offering special advantages and drawbacks. For demanding applications, hard metals offer strength and durability; soft metals provide cost savings and ease of machining. Knowing these variations helps companies maximise their CNC machining techniques, thereby ensuring the optimal balance of cost, performance, and efficiency for their projects.