For many motorcyclists, motorcycling customising is a passion and an art. Custom motorcycle components are a great approach to differentiate a bike, whether for looks, performance improvement, or personalising. Among the many production processes accessible for personalising, CNC machining is among the most sophisticated and accurate ones. It makes it possible to produce excellent, custom-made components fulfilling certain design and performance requirements.

This article will tell you how CNC machining is transforming the customising of motorcycle components, its advantages, and the many items that this technique may produce.

How CNC Machining Works?

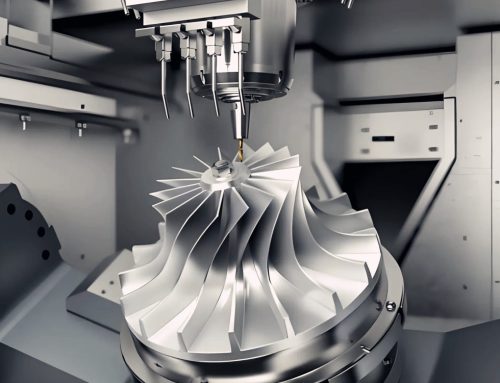

Using computer-operated tools, subtractive manufacturing—CNC machining—removes material from a solid block (workpiece) to produce exact components. Starting with a computerised 3D model, the procedure moves into machine instructions to precisely carve out the intended form. Among the many materials CNC machines can deal with are aluminium, steel, titanium, and even plastic.

Benefits of CNC Machining for Motorcycle Customization

By offering motorcyclists premium, custom-made components that enhance both performance and appearance, CNC machining has fundamentally changed the motorcycle customising market. CNC machining guarantees accuracy, durability, and infinite design options, whether for a simple decorative update or a functional improvement. The main benefits of using CNC machining for motorbike modification are listed below.

- Great accuracy and precision

Perfect precision provided by CNC machining guarantees that custom motorcycle components fit exactly without requiring any adjustments. For performance-related components like engine and suspension elements, CNC machines’ accuracy enables tolerances as close as ±0.005mm—which is vital.

- Strength and Longevity

Cut from solid metal blocks, CNC-machined parts are more robust and wear and tear resistant than mass-produced cast or plastic components. Stronger pieces resulting from this may survive in very hostile environments.

- Flexibility and Individualization

CNC machining almost removes any design restriction. Motorcycle aficionados may design original parts that fit their taste and need for functionality. Custom components could be created with improved aerodynamics, weight reduction, or aesthetic improvement in mind.

- Effective Manufacturing Minimising Mistakes

CNC machining is computer-operated, hence human mistake is much reduced. Using CAD (Computer-Aided Design) tools guarantees that every component is produced precisely as designed, therefore reducing waste and discrepancies.

- Broad Materials Range

CNC machining accommodates a variety of materials so that riders may select from lightweight aluminium for speed and agility, titanium for strength and corrosion resistance, or even carbon fibre-infused composites for a futuristic appearance.

Custom Motorcycle Parts Made Using CNC Machining

For motorcyclists who want to improve the appearance and performance of their motorcycles, customising motorcycle components with CNC creates a universe of possibilities. CNC machining offers unmatched accuracy and adaptability for everything from weight reduction to aerodynamic improvement to just a personal touch. These are some of the most often personalised motorbike components produced using CNC technology.

- Custom Wheels and Rims

Performance as well as appearance depend critically on wheels. Custom rims produced by CNC machining let riders have distinctive designs, increased strength, and weight reduction for greater acceleration and handling.

- Engine parts

Custom engine components like cylinder heads, pistons, camshafts, and throttle bodies abound in performance tuning. By guaranteeing perfect production of these parts, CNC machining increases power output and efficiency.

- Manage controls and handlebars.

Custom CNC-machined handlebars, brake and clutch levers, and grips provide riders seeking a unique riding experience choice. These components may be moulded to improve both appearance and ergonomics.

- Individual Exhaust Systems

Exhaust systems impact not only performance but also the sound and general style of a motorbike. High-performance exhaust tips, headers, and muffler components may be produced using CNC machining, therefore guaranteeing improved airflow and original design.

- Swingarms and Frame

Custom frames, swingarms, and subframes with superior stress distribution and durability allow CNC machining to provide those looking for a lightweight yet durable frame the means to manufacture.

- Rearsets and Foot Pegues

CNC machining allows adjustable and fashionable rear sets and footpegs, thereby improving grip, control, and a customised appearance to fit the rider’s taste.

- Gas Caps and Fuel Tanks

Designed using CNC machining, bespoke gas caps and gasoline tank covers provide a stylish, personalised touch while guaranteeing a safe and exact fit.

- Clutch and Brake Components

From master cylinders to custom calliper brackets, CNC machining makes performance-oriented brake and clutch components possible that enhance control and safety.

Custom Motorcycle Parts CNC Machining Process

A sequence of well-defined processes in CNC machining guarantees custom motorcycle components great accuracy and quality. From the first design stage to the last finishing touches, every step is vital in creating strong and visually beautiful parts. The CNC machining procedure used in motorcycle modification is broken out below in great depth.

- Prototyping Design

- The procedure begins with the CAD software design of the item

- after the design is complete

- 3D printing or CNC milling may provide a prototype for testing and improvement

- Selection of Materials

- Selecting the appropriate component depending on durability, weight, and strength criteria

- Among popular possibilities are titanium (high strength), aluminium (lightweight and corrosion-resistant), and stainless steel (durable and wear-resistant).

- CNC Manufacturing Method

- From a solid block, the CNC machine shapes the item using many cutting tools.

- Multi-axis CNC machines (3-axis, 4-axis, or 5-axis) allow for complicated geometries and detailed work.

- Surface Treatment and Finish

The last section is polished, anodised, powder coated, or painted to improve appearance and guard against corrosion. For branding or personalising, certain elements might potentially be laser-etched or engraved.

CNC Machining’s Future: Motorcycle Customization

Future CNC machining in motorcycle customising looks bright with developments in artificial intelligence-driven machining, 5-axis CNC technology, and hybrid production. High-speed machining and automated design optimisation will improve accuracy, efficiency, and accessibility to bespoke components yet further. Furthermore, included in CNC systems are machine learning techniques meant to enhance predictive maintenance and adaptive machining. Using new composites and smart materials will also enable lighter and stronger components, hence improving both fuel economy and performance. Completely autonomous CNC manufacturing lines might make bespoke motorcycle components even more reasonably priced and accessible to fans all over as automation and robots keep developing.

In summary

With unparalleled accuracy, durability, and design freedom, CNC machining has revolutionised the customising of motorcycle components. CNC-machined components provide the best answer whether your riding is informal and you want to improve looks or professional racing, and performance enhancement is your goal.

CNC machining will always be a pillar in the realm of motorcycle modification as technology develops, stretching the bounds of design and performance.

Motorcyclists may realise their dream designs by using this innovative production technique, therefore guaranteeing a distinctive and individual riding experience.