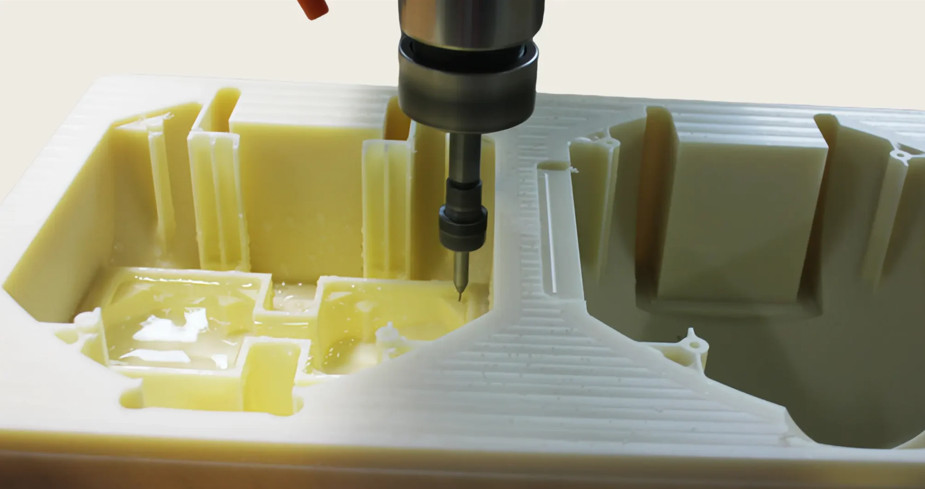

CNC milling is now a vital technology for product development, manufacturing, and prototyping. Plastics, particularly ABS , are just as significant as metals like steel,brass and aluminium, which frequently take centre stage in discussions. Because ABS is lightweight, affordable, long-lasting, and simple to form, it is utilized extensively. It can be found in toys, consumer electronics, medical equipment, automobile parts, enclosures, and even aircraft prototypes.

Because ABS is soft engineering plastic material, inexpensive, and widely used, CNC milling it might seem simple, but producing reliable, high-quality results involves much more than just operating a machine. ABS has unique problems that require careful consideration and expertise, including as heat sensitivity, dimensional instability, and chip-related problems. Understanding ABS’s thermoplastic behavior and developing machining techniques to preserve stability, accuracy, and surface quality throughout the process are essential to mastering the material.

Understanding ABS machining

ABS machining is more complicated than it appears at first. ABS has its own engineering problems, such as melting, warping, chipping, dimensional instability, and surface polish problems, while being softer than metals. For ABS to be successfully CNC milled, the proper tools, setups, parameters, and operator skills are required. The machinist’s skill set is important in addition to the technical specifications. Reliable results are based on a combination of deep understanding of polymer behavior, good CAM programming skills, familiarity with adaptive machining processes, and the capacity to identify and resolve on-machine problems. ABS, in contrast to metals, necessitates ongoing precision, heat control, and minute modifications that can only be learned and practiced.

This technical content covers the main obstacles, recommended practices, and technical know-how required to achieve excellent outcomes when CNC milling ABS plastic.

1.Knowing ABS Plastic: The Reasons Behind Its Distinct Behavior

The components of ABS, an engineered thermoplastic, are:

- Acrylonitrile: Provides stiffness and resilience to chemicals

- Butadiene: Enhances durability and impact resistance

- Styrene provides gloss and moldability.It has a melting point of 210–240°C, which is significantly lower than that of metals. Heat control is crucial because of the direct impact this low melting point has on machining behavior.

Important Factors Influencing Machining

Flexibility and softness: More likely to distort when clamping

Poor chip evacuation: Gumming and melting are caused by a low melting point.

Dimensional errors: It is caused by thermal expansion.

Reduced rigidity: Under tool pressure, it may shake, clatter, and deflect

Before machining ABS, operators can set realistic expectations by understanding these basics.

2.The Difficulties of ABS Milling

ABS is simple to mold and 3D print, but CNC milling is a different matter. The following are the most typical difficulties:

2.1 Melting and Heat Buildup

Controlling the temperature is the most challenging aspect of milling ABS. Heat buildup causes the material to melt or soften, which can lead to:

- Chips that stick

- Clogging of the tool

- Inadequate surface polish

- Dimensional errors

Inadequate chip evacuation or high spindle speeds are the main sources of heat.

2.2 Warping of Workpieces

ABS is susceptible to deformation when subjected to mechanical force or heat.

Warping may happen:

- When cutting aggressively

- When taking down thin walls

- Because of incorrect fixturing

- from imbalanced stressors within

- Poor assembly fit and erroneous dimensions are the results of warping.

2.3 Chipping and Burring

ABS creates stringy chips that, in contrast to brittle plastics, can:

- Encircle the instrument.

- Melted and deposited on the surface

- Make the edges fuzzy.

- Harm the part’s finish

It’s crucial to keep your equipment sharp and to evacuate chips properly.

2.4 Deflection of Tools

Because ABS is soft, machinists frequently push the tools harder, believing that cutting it will be simple.However, pushing too quickly results in:

- Flexing a tool

- Dimensional mistakes

- Marks of chatter

- Either overcutting or undercutting

- Instability results from a combination of strong cutting forces and low material stiffness.

2.5 Instability in Dimensions

ABS greatly expands as the temperature rises.

A temperature change of even a few degrees can result in:

- Drift in hole size

- Variations in thickness

- Deformities of slots

- Problems with tolerance in built components

For this reason, precise temperature control is essential for milling.

3.Best Practices: Practical Advice for Milling ABS Plastic

A deliberate strategy is necessary to overcome the difficulties associated with ABS milling.

Here are the best, tried-and-true methods.

3.1 Make Use of Sharp Instruments, Ideally Single-Flute Cutters

Performance is significantly impacted by the tool selection. ABS benefits greatly from single-flute end mills since they:

- Reduce the amount of heat

- Remove chips more effectively.

- Cut down on melting

- Make the edges cleaner

- Additional tool suggestions:

For vigorous chip evacuation in deep pockets, use up-cut end mills.When milling thin sheets, use down-cut end mills to provide clean upper edges.Fluffle instruments that have been polished to reduce friction .Never use worn tools since the material will heat up quickly on dull edges.

3.2 Increased Feed Rate, Reduced Spindle Speed

For plastics, conventional wisdom states: Slow pace, fast feed. Why? because high feeds aid in the speedy removal of chips and lower spindle RPM lowers heat.

Suggested initial parameters:

- RPM range for the spindle: 8,000–12,000

- Rate of feeding: 1000–2500 mm/min

- DOC (depth of cut): 0.5–2 mm

- 20–40% of the tool diameter is the step-over.

- Adapt based on tool size and stiffness.

3.3 Maintain Workpiece Coolness

It’s crucial to cool down when Machining ABS.

Utilize:

- Air blast is the greatest choice.

- Mist coolant (if used sparingly, safe)

- Using vacuum extraction to remove chips

- Using a continuous air stream during dry machining

- Avoid using flood coolant as it might lead to warping and chemical absorption.

3.4 Correct Clamping and Fixturing

Because ABS can distort while under pressure, use:

- Gentle jaws

- Beds with vacuum

- Two-sided tape

- Clamps with low pressure

To reduce vibration, make sure the part is supported uniformly. Vacuum tables work quite well for huge sheets.

3.5 Start Rough, Then Complete

Use a two-step machining approach at all times:

First Step: Roughing

- Quickly remove bulk stuff.

- Leave a stock of 0.2–0.4 mm.

Second Step : Completing

- Employ sharp implements.

- Make very light passes.

- Reduce the speed and feed a little.

This prevents melting and produces a smooth, polished appearance.

3.6 Toolpath Strategy for Control

Accuracy and heat are impacted by toolpath choices.

Suggested:

- Adaptive clearing to lessen the burden on the tool

- Climb milling to enhance the quality of the edges

- Techniques for high-speed machining (HSM) that guarantee constant tool engagement

- Steer clear of abrupt direction changes that could make the tool rub rather than cut.

3.7 Avoid Rewelding Chips

Because ABS chips are sticky, make sure you always:

- Chip evacuation that never stops

- Chips blown by the air

- At the nozzle, compressed air

- Regular cleaning throughout extended operations

This avoids surface damage and keeps the flutes free.

4.Crucial Technical Proficiencies for ABS Machinists

Understanding material behavior, cutting parameters, and machine knowledge are all necessary for CNC milling ABS. The following are the fundamental abilities a machinist has to have:

4.1 Comprehending Polymer Behavior

- In contrast to metals, polymers

- Flex

- Heat more quickly

- Extend farther

- react to cutting pressure in different ways.

A machinist needs to understand how temperature impacts ABS and how to keep it stable.

4.2 Proficiency with Tool Selection

Selecting:

Accurate number of flutes

Material for the tool (carbide preferable)

Coating (polished or unpolished instruments)

Tool geometry

It is essential to guaranteeing precise cutting.

4.3 Cutting Parameter Mastery

Machinists need to be able to set:

RPM

Rate of feed

Cut depth

Step-over

Strategies for entry and exit

Melting or distortion might result from a tiny error.

4.4 Skills for Fixturing and Workholding

Due to ABS’s flexibility, a thorough understanding of fixturing procedures is required:

Clamping with a vacuum

Design of a soft jaw

Decisions about workpiece orientation

Careful clamping is necessary to prevent distortion in even the simplest elements.

4.5 Proficiency in CAM Programming

Proficiency in CAM programming aids in:

Creating effective toolpaths

Adaptive clearing

Smoothly navigating corners

Reducing the buildup of heat

CAM expertise chooses the ideal ratio of speed to quality.

4.6 Methods for Surface Finishing

ABS calls for finishing methods like:

Light moves through

Shining

Painted

Plating

A thorough understanding of post-processing significantly improves quality.

4.7 Process optimization and troubleshooting

Expert machinists:

Recognize melting indicators

Modify the speed and feed.

Modify the toolpaths

Resolve vibration problems

Enhance the removal of chips

Repeatable quality is ensured by ongoing optimization.

5.CNC Milling vs Other Techniques for ABS Manufacturing

Compare CNC milling to other options to see where it stands:

5.1 Milling with CNC

Benefits:

High precision in dimensions

Sharp characteristics

Great for working ABS prototype

Strong mechanical qualities because of the solid block

Demands cautious heat control.

5.2 Molding by Injection

Ideal for large-scale manufacturing, but costly for prototyping because of mold costs.

5.3 ABS 3D Printing

Excellent for rapid prototypes, but:

Layer lines are discernible.

Anisotropic strength

There is less dimensional accuracy.

5.4 ABS Laser Cutting

ABS is typically avoided due to its extreme melting and harmful emissions.

When production-quality prototypes, strength, and precision are needed, CNC milling shines out.

6.Industries That Frequently Use ABS Machines

ABS is widely used in:

Electronic devices

Enclosures

Accommodations

Mounts

Automobile

Internal elements

The brackets

Switches

Medical

Casings for devices

Parts of lab equipment

Consumer Products

Playthings

Appliances for the home

The aviation industry

Prototypes that are lightweight

Fit-check models

ABS is one of the most adaptable plastics due to its affordability, durability, and ease of machining.

7.ABS Machined Parts Quality Inspection

To guarantee that components fulfill requirements:

7.1 Measurement Verifications

When precise tolerances are required, calipers, micrometers, or CMM are used.

7.2 Analysis of Surface Finish

Make sure:

Absence of melt marks

Absence of burrs

walls that are smooth

7.3 Testing for functionality

Verify:

Fit

Engagement of the fastener

Strength of snap-fit

7.4 Check for Temperature Stability

Analyze performance in the anticipated operational environment.

8.Typical Errors to Steer Clear of When ABS Machining

When using ABS, even experienced machinists might make mistakes. Steer clear of:

- Too high a running spindle speed

- Using tools that are worn out or unpolished

- Using too much clamping force

- Overuse of flood coolant

- Ignoring the accumulation of chips

- Creating thin, unsupported walls

- Making deep cuts that cause the part to heat up

- Longer tool life and consistent quality are ensured by avoiding these errors.

Conclusion: Using ABS to Achieve Superior CNC Milling Results

Due to ABS is a soft plastic, CNC milling it might seem easy, but it actually requires precise technical abilities, careful heat management, cutting strategy, and tooling choices. When properly managed, ABS can provide:

- Outstanding surface quality

- High precision in dimensions

- Robust functional components

- Quick prototypes

- Economical manufacturing

Machinists can reliably produce high-performance ABS components by understanding its challenges and adhering to recommended practices. Gaining proficiency in ABS CNC milling gives you a competitive edge in contemporary manufacturing, whether you’re creating enclosures, engineering prototypes, automobile parts, or consumer items. Choosing sharp, suitable tools, adjusting spindle speeds and feed rates to reduce heat accumulation, guaranteeing dependable chip evacuation, and employing controlled fixturing techniques to avoid deformation are the foundation of a successful CNC milling workflow for ABS. Every stage, from toolpath optimization to the use of specialized cooling techniques, contributes to preventing ABS from melting, warping, or losing its dimensional integrity. These methods increase operational efficiency and prolong tool life in addition to improving part quality.

One of the best techniques for creating precise, useful ABS components utilized in a variety of industries, including consumer electronics, medical equipment, and automobiles, is CNC milling. The ability to process ABS to a high standard is becoming increasingly valuable as modern manufacturing continues to advance. Manufacturers may fully utilize ABS and produce products that satisfy the highest requirements for performance, consistency, and durability by combining technical expertise, material understanding, and optimized processes.