The process of turning a basic idea into a fully functional product is more crucial than ever in today’s fast-paced, innovation-driven world. The “concept to prototype” process is the foundation of effective product development, regardless of your role as a manufacturer, engineer, business founder, or product designer. It turns ideas into reality, verifies functionality, lowers risk, and lays the groundwork for manufacturing that can scale.

This article will tell you the steps in the process, why they matter, and how businesses can improve their chances of successfully and confidently launching high-quality products.

1.The Importance of the Concept-to-Prototype Process

Every innovative product starts as an idea—a dissatisfaction, an observation, or an unfulfilled need. But ideas by themselves are worthless until they are developed, tested, and improved. Prototyping becomes essential at this point.

1.1 Lowers the Risk

Teams can test viability with a prototype before investing heavily. Early detection of design defects, material problems, and usability issues can save resources, time, and money.

1.2 Transforms Intangible Vision into Physical Reality

Investors, engineers, and manufacturers are among the many stakeholders who find it difficult to visualize an idea based only on words. A prototype bridges the gap between vision and implementation by effectively communicating the concept.

1.3 Promotes Innovation

Experimentation is encouraged via prototyping. Teams can find ways to enhance, streamline, or reconsider functionality by viewing, handling, and testing a model. Innovation is fueled by this continual cycle.

1.4 Quickens the Readiness for Manufacturing

Manufacturability issues are revealed by a well-designed prototype long before mass production starts. This aids engineers in improving assembly procedures, material selection, and tolerances.

2.Crucial Phases: From Idea to Model

2.1 Researching Ideas and Identifying Problems

Clarity is crucial before drawing a design. This phase entails:

- Determining the issue

- Recognizing user requirements

- Examining the gaps in the market

- Investigating rival products

This study makes that the concept addresses a practical need and has a probability of succeeding in the marketplace.

2.2 Development of Concepts

Teams start generating ideas for possible remedies as soon as the problem is identified. This could consist of:

- rough drawings

- First technical notes

- Fundamental characteristics

- The initial architecture of the product

Usually, a number of ideas are investigated before the most practical course is selected.

2.3 Study of Feasibility

A feasibility analysis establishes whether the idea can be realized in a practical manner. A few things to think about are:

- Price and the availability of materials

- Technical specifications

- Compliance and safety

- Limitations in manufacturing

- It’s time to go to market.

By taking this step, one can steer clear of concepts that are financially unsound or unworkable.

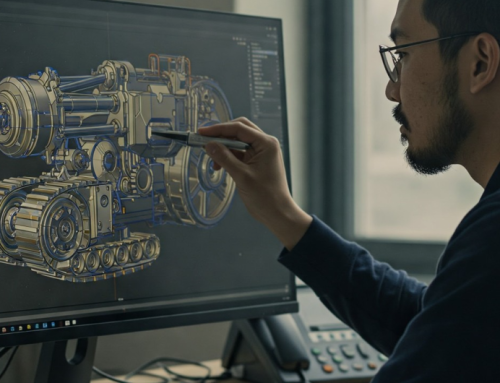

2.4 CAD Design and 3D Modeling

Engineers use CAD tools to generate digital drawings after deciding on a concept. Among these models are:

Tolerances and dimensions

Specifications for materials

Instructions for assembly

Layout of internal components

CAD models guarantee accuracy and serve as manufacturing and prototyping blueprints.

2.5 Development of Prototypes

Depending on the stage of development, prototyping can take many different forms:

Prototypes with low fidelity

Simple mockups are used to assess concept flow, ergonomics, and shape.

High-Reliability Models

Functional models for assessing:

Performance of mechanical systems

Behavior of materials

Beauty

Interaction between users

Commonly used technologies include vacuum casting, 3D printing, laser cutting, and CNC machining.

3.Prototyping’s Advantages for Product Development

3.1 Initial Validation and Testing

A prototype aids in team validation.

Strength of product

Usability

Security

Experience of the user

When working with a physical object, problems that might not show up on paper frequently surface.

3.2 Making Knowledgeable Decisions

Prototyping eliminates uncertainty. Instead of being based on conjecture or theoretical computations, decisions are now data-driven and informed by actual testing.

3.3 Better User-Centric Design

Early user testing is made possible by prototypes. Invaluable input is provided on look, comfort, and usability. Instead of making assumptions, it assists teams in customizing goods to meet actual client wants.

3.4 Economic Effectiveness

Resolving issues after manufacturing can be quite costly. Early mistake minimization through prototyping lowers tooling costs, rework, delays, and material waste.

3.5 Encourages Stakeholder and Investor Buy-In

Compared to a concept slide, a functional prototype is much more persuasive. It raises the likelihood of getting money or leadership approval and fosters trust.

4.Various Prototype Types and Their Uses

4.1 Conceptual Models

used in the early stages to convey the product’s concept, dimensions, and fundamental shape.

4.2 Working Prototypes

Pay attention to performance. Engineers test components’ functionality, interactions, and reaction under stress.

4.3 Aesthetic and Visual Prototypes

Pay attention to the product’s feel, look, and ergonomics—all of which are crucial for designs that are aimed at consumers.

4.4 Prototypes Before Production

These are nearly identical copies of the finished product that are used to:

Examine production techniques.

Verify tolerances.

Verify adherence

Complete the material selections.

The product’s suitability for mass production is assessed using pre-production prototypes.

5.Rapid Prototyping Technologies’ Function

Product development has been transformed by the emergence of contemporary prototype technology.

5.1 The use of 3D printing

Ideal for early testing, complex geometry, and rapid iterations.

5.2 Machining with CNC

Perfect for working prototypes that need:

- High power

- Accuracy

- Performance ready for production

5.3 Casting by Vacuum

Excellent for pilot testing with end-use materials or small batch production.

5.4 Cutting using a laser

helpful for producing flat components, panels, and housings with a high degree of accuracy.

Even small teams may more easily access innovation thanks to rapid prototyping, which also shortens development cycles.

6.Typical Obstacles in the Concept-to-Prototype Process

Teams must overcome a number of obstacles in spite of its benefits:

6.1 Indeterminate Needs

Costly changes and misalignment result from poorly defined requirements.

6.2 Inconsistency in Material

Poor performance or erroneous testing can arise from selecting the incorrect materials.

6.3 Overly Complicated Designs

Early on, having too many features might confuse users and lengthen the development process.

6.4 Financial Limitations

Investment is necessary for prototyping; expenses might quickly increase without careful planning.

6.5 Quality vs. Speed

Rushing the process frequently results in compromised manufacturing, testing, and accuracy.

With smart choices and methodical workflow management, successful teams strike a balance between all of these elements.

How Prototyping Affects the Success of the Finished Product

The possibility that a product will succeed in the market is greatly increased by a well-executed prototype. Teams can use a prototype to:

- Recognize issues early

- Verify the interest of the client

- Make sure it can be manufactured.

- Boost the final product’s quality

- Cut down on the launch time

Above all, prototypes enable teams to increase internal and external trust that the product is viable, appealing, and prepared for additional investment.

Conclusion

The process of developing a product from concept to prototype is the cornerstone of successful product innovation and goes much beyond a technical necessity. Before mass manufacturing starts, it turns concepts into physical artifacts, finds design problems, and verifies functionality. Prototyping guarantees that the finished product genuinely satisfies user expectations while also saving time, money, and creativity. Given how quickly businesses throughout the world are innovating, understanding the concept-to-prototype process is crucial for any company or individual looking to launch high-quality goods. Organizations may realize ideas with accuracy, confidence, and long-term success by investing in strategic prototyping, careful design, and ongoing iteration.