Mechanical engineering is not an exception to how artificial intelligence (AI) is changing industries worldwide. Mechanical engineering is currently embracing a new era of intelligent automation, predictive analytics, and data-driven innovation, after previously being solely reliant on manual design, prototyping, and manufacturing.

AI is now the engine powering more intelligent product design, effective maintenance, sophisticated production processes, and environmentally friendly engineering techniques. It is reinventing how engineers think, create, and work, not merely streamlining current procedures.

This blog offers a thorough grasp of how artificial intelligence (AI) is changing mechanical engineering, including its applications in robotics, design, modeling, manufacturing, predictive maintenance, and the potential and difficulties it presents for the field.

1.Artificial Intelligence in Mechanical Engineering

The emergence of CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) tools, which employed a restricted number of algorithms for design automation, marked the beginning of the progressive integration of AI into mechanical engineering. These systems are now much more potent due to the advancements in machine learning (ML), deep learning, and neural networks.

Machines can now carry out jobs that formerly required human intelligence thanks to modern AI systems’ ability to assess data, learn from it, and make judgments.

AI is now used by mechanical engineers for:

- Automating design procedures that are repeated

- Improving the accuracy of simulations

- Foreseeing system malfunctions before they happen

- Making production lines more efficient

- Increasing sustainability and energy efficiency

The outcome? increased dependability, reduced expenses, and quicker innovation cycles.

2.AI in Simulation and Design

One of AI’s most innovative uses in mechanical engineering is generative design. Engineers use AI software to enter manufacturing processes, material limitations, and performance targets in place of manually sketching designs. After that, the system produces thousands of optimal design iterations, which frequently result in imaginative, organic-looking structures that function better than those created by humans.

For instance:

AI-driven design is used by automakers to produce robust yet lightweight vehicle structures.

Generative algorithms are used by aerospace engineers to minimize material weight while preserving safety margins.

AI algorithms are used by programs like Siemens NX, Autodesk Fusion 360, and ANSYS Discovery Live to optimize material distribution, explore design options, and significantly shorten time-to-market.

Simulation Driven by AI

Conventional simulation methods require a lot of processing and time. AI improves these simulations by executing real-time simulations, forecasting results, and learning from prior test data.

Engineers can save weeks or even months in the development cycle by using AI-based predictive modeling to understand how designs will perform under various loads or temperatures without conducting extensive physical testing.

3.Artificial Intelligence in Production and Manufacturing

Industry 4.0, or AI-driven smart manufacturing, incorporates automation, IoT (Internet of Things), and data analytics into production systems. Real-time communication between machines allows them to share performance information and make autonomous adjustments to maintain optimal production.

For instance:

On an assembly line, AI algorithms are able to identify inefficiencies or bottlenecks and automatically adjust the operation.

During production, vision-based AI systems check the quality of the product, minimizing waste and human error.

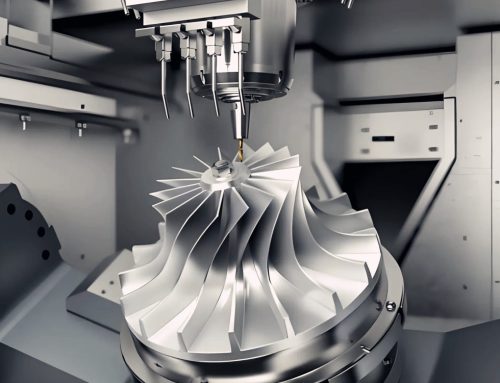

Process optimization and CNC machining

Cutting settings are dynamically adjusted by AI-powered CNC (Computer Numerical Control) devices using sensors and feedback systems. Particularly for materials that are challenging to mill, such as nickel alloys or titanium, these “intelligent machines” can forecast tool wear, optimize feed rates, and guarantee constant precision.

3D printing, or additive manufacturing

AI improves printing parameters, layer orientation, and material flow in additive manufacturing to increase precision and reduce flaws. In order to improve quality and use less material, deep learning models automatically modify settings and forecast probable build failures.

4.AI in Condition Monitoring and Predictive Maintenance

One of the most expensive problems with mechanical systems is downtime. Conventional maintenance techniques, such as routine service, frequently result in unplanned malfunctions or needless shutdowns.

- AI revolutionizes maintenance by making prescriptive and predictive solutions possible:

- Predictive maintenance: AI forecasts when a component is likely to break by using machine learning models built on vibration, temperature, and sound data.

- Prescriptive maintenance goes one step further by offering recommendations for the best way to avoid failure.

- For example, sensors in pumps, compressors, or turbines continuously gather performance data. AI examines this data to predict malfunctions, plan maintenance at the best periods, and lower operating expenses.

This prolongs the life of mechanical assets and increases equipment reliability.

5.Automation and Robotics

In mechanical engineering, AI-driven robotics has completely changed the processes of manufacturing, assembly, and inspection.

Collaborative Robots (Cobots): AI-driven cobots safely assist people while picking up new skills and adjusting to various activities.

Autonomous Robots: These machines carry out repetitive, risky, or precision-dependent tasks using computer vision, deep learning, and path-planning algorithms.

Robots for quality inspection that are outfitted with AI vision systems are able to identify even the smallest flaws, guaranteeing manufacturing that is flawless.

In order to create genuinely autonomous production ecosystems, mechanical engineers are increasingly designing robotic systems that are capable of self-optimization and self-diagnosis.

6.AI in Fluid and Thermal Systems

AI is essential for improving fluid dynamics and temperature control in mechanical systems.

AI algorithms, for instance, evaluate environmental data in HVAC (Heating, Ventilation, and Air Conditioning) systems to dynamically optimize temperature, airflow, and energy use.

computing fluid dynamics (CFD) models with AI support can forecast fluid behavior more precisely and at a fraction of the computing cost of conventional simulations in fluid mechanics. These methods are very useful for designing turbine efficiency and automotive aerodynamics.

7.Artificial Intelligence and Ecological Design

One of the main topics in contemporary mechanical engineering is sustainability. AI contributes to leaner, more energy-efficient, and greener engineering processes.

Material Optimization: To cut waste and carbon emissions, AI algorithms select the best materials.

Energy Management: AI is used in smart factories to maximize machine energy usage.

Lifecycle Assessment: AI technologies assist engineers in designing for durability and recyclability by forecasting how goods will function over time.

This combination of intelligence and sustainability signifies the shift to environmentally friendly mechanical systems that maximize performance while reducing their negative effects on the environment.

8.Engineering Collaboration Between Humans and AI

AI is enhancing engineers’ skills, not taking their place. Collaboration between humans and AI is key to the future of mechanical engineering. While AI manages repetitive and data-intensive activities, engineers interpret data insights, make strategic design decisions, and oversee autonomous systems.

This collaboration makes it possible for:

- Quicker cycles of innovation

- Improved accuracy

- Increased security in dangerous situations

- Constant learning and process improvement

As a result, engineers may concentrate on strategic planning, creativity, and problem-solving while intelligent systems handle complex computing tasks.

9.Adoption of AI in Mechanical Engineering Presents Difficulties

There are a number of obstacles to overcome when incorporating AI into mechanical engineering, despite its enormous potential:

Data Quality & Availability: AI relies on extensive, precise datasets. Models with errors may result from inconsistent or insufficient data.

High Implementation Costs: A substantial investment is needed to set up sensors, AI systems, and IoT infrastructure.

Skill Gaps: Data science, coding, and AI algorithms are interdisciplinary fields that engineers need to learn.

Cybersecurity Risks: Systems are more vulnerable to cyberattacks and data breaches as a result of increased interconnectedness.

Ethical & Decision Accountability: AI-driven choices need to be open and explicable, particularly in sectors where safety is a top priority.

To overcome these obstacles and guarantee the ethical, effective, and secure deployment of AI, engineers, data scientists, and legislators must work together.

10.Artificial Intelligence’s Prospects in Mechanical Engineering

An even more thorough integration of AI technology into mechanical systems is anticipated in the future:

Digital twins are artificial intelligence (AI)-powered virtual versions of real systems that are used for predictive analysis and real-time performance monitoring.

AI-run factories with self-diagnosing, self-repairing, and self-optimizing machinery are known as autonomous factories.

Quantum-AI Hybrid Models: Using AI and quantum computing together to process intricate simulations more quickly than before.

AI-Driven Education: Machine learning, data analytics, and automation control will become more prevalent in mechanical engineering curricula.

Essentially, mechanical engineering is developing into intelligent mechanical systems engineering, where machines can think and creativity and computing collide.

Conclusion

AI has a significant and wide-ranging effect on mechanical engineering. AI has revolutionized every phase of the engineering lifecycle, from automating design to increasing productivity, anticipating faults, and promoting sustainability.

By adopting AI, mechanical engineers are creating intelligent systems that can adapt, learn, and change rather than merely building machines. The cooperation of artificial intelligence and human experience will keep pushing the limits of efficiency, creativity, and environmental responsibility as we head toward a future when smart technologies rule the day.

AI is reinventing what is mechanically possible, not just improving mechanical engineering.