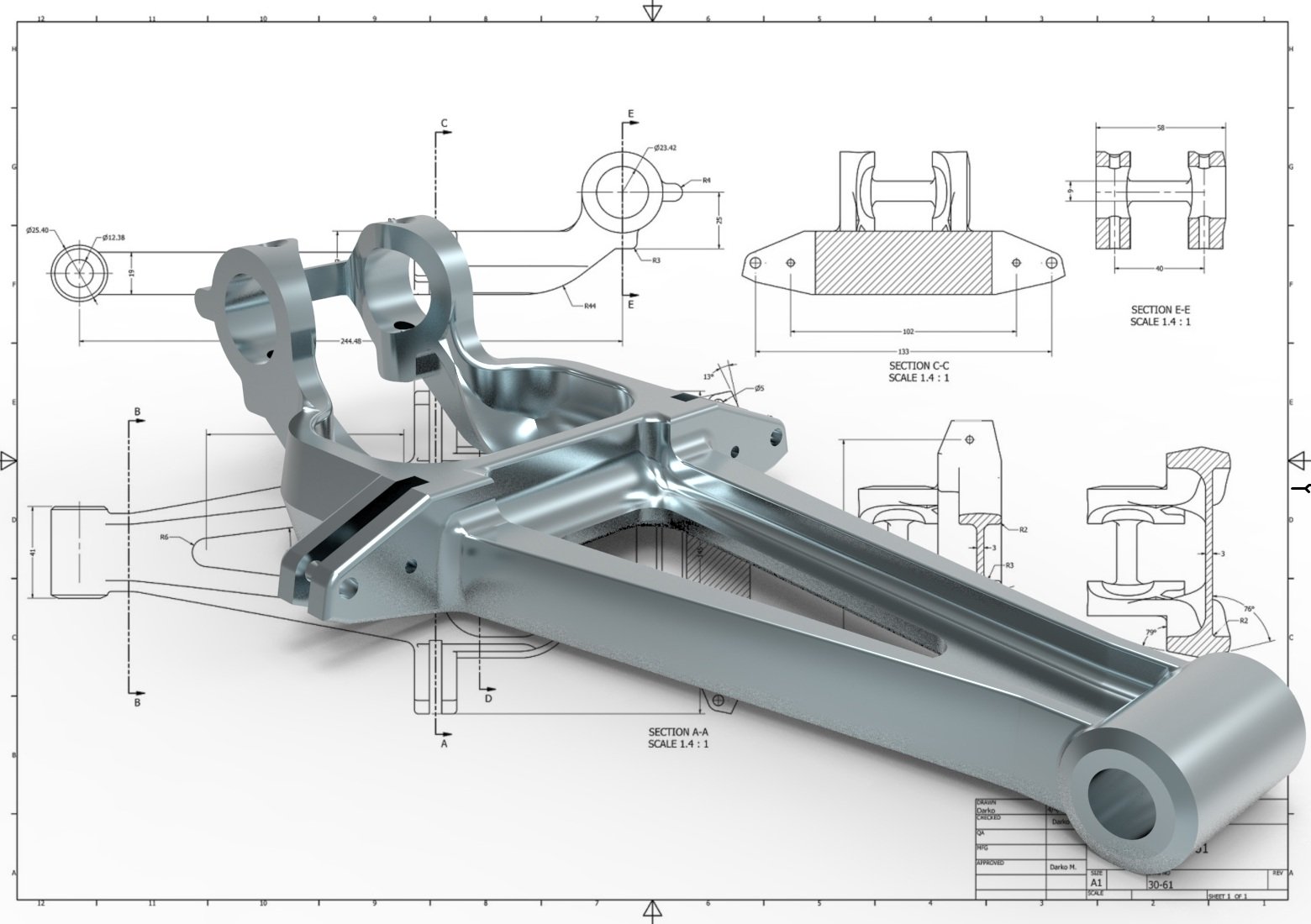

Turning Your Design Into Reality

With more than 18 state-of-the-art machines and support equipment in our modern facility, we’re equipped to manufacture, inspect, assemble and deliver virtually any precision products you desire, We are an ethical and innovative supplier of precision components, partnering with customers to meet their needs, while setting the standard in the industry. A leader of Precision machining processes in Southern China. We provide precision machined parts to customers all over the world.

Our engineering is proud to supply top-quality Custom CNC Parts. UYEE advanced machining & turning centers allow for rapid delivery of prototypes, short run production order, reduced tooling costs, and high tolerances, all backed by our skilled technicians. Our CNC machines equipments are ideal for working with stainless steel, aluminum, brass, titanium, and other specialty materials. We can also provide a number of custom finishing services to meet customer’s different requirements. Such as: anodizing, heat treating, welding, painting, plating ..etc.

What is CNC Milling & Turning?

1)CNC milling machines are often classified by the number of axis that they have .The axis for horizontal movement are called X and Y. And the axis for vertical movement is called Z. Usually a common milling machine often have these three axis X,Y,Z. Now with machine technology constantly development and the requirements of milling complex shape of part,5-axis,6-axis more common implicated in this industry. CNC Milled Parts are widely used in lots of industry, such as: automotive, medical, oil, defense, kitchen faucet.

2)CNC turning is often used for manufacturing the cylinder shape products. It’s a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix tool path by moving more or less linearly while the work piece rotates. The tool’s axes of movement may be literally a straight line, or they may be along some set of curves or angles, but they are essentially lineal. So you can see that CNC turned parts is a common manufacturing process that hold a round material in a chuck and rotated to remove material to get the desired components. The production process is simple.

Cost Savings and On Time Delivery Of Custom Machined Parts

As a leader in specialty precision machining manufacturer, UYEE has the premium materials and advanced equipment to machine custom parts to your exact project specifications. From a single prototype to complex components, we have the manufacturing capabilities and engineering support to machine custom parts to fit your needs. To continually improve our product quality and efficiency in production, We invest a large amount of time and money into the research and development of new manufacturing strategies and techniques. And also, train our technicians to get new skills. This helps us hone our skills as problem-solvers, and we often apply our knowledge to address specific manufacturing issues, especially those centered around the production of close tolerance parts. We specialized in offering services of custom machined parts according to the clients’ drawing or sample, for both prototype and low volume jobs. We have a full inspection department to assure your parts are correct. Our QC team not only checks the finished parts, but also checking the raw material before coming into production. Dimensional inspection reports can also be obtained by request.

Custom Precision CNC Aluminum Parts

Aluminum is a soft metal material compare with other metals. Aluminum parts machining is the most economical because they can be use CNC machining and turning for shorter periods of time than other metals. Aluminum machined parts also have added strength, corrosion, and rust resistance due to a protective layer that forms when exposed to the atmosphere. Our knowledgeable programming team reviews each project in-depth to assess cost, validate manufacturability, and ensure your parts are processed with maximum efficiency. Furthermore, aluminum machining products are chemical resistant, electrically conductive, malleable, and possess high strength. For these reasons and more, UYEE has dedicated itself to becoming the leader in CNC Aluminum machining, Our fabrication experts analyze your project and process your parts on the most efficient machining center for the job to get you the most for your money.

As a Machined parts manufacturer, UYEE offers a variety of other machining services to take your unique job all the way from conception to realization with help from our skilled technicians. in the meantime providing conventional milling, drilling, grinding. We are knowledgeable in machining a variety of metals and plastics. Our years of experience in providing Precision machining services results in maximum efficiency as well as maximum savings. We provide machining and turning from CNC prototyping through low volume production to get you just the right part you require! Our facilities enable us to further add value on our products by machining and supporting our customers with the fast turnaround of the high precision finish machined parts.

The automotive industry is the technological trendsetter among manufacturing industries. It keeps evolving on fast pace and is a driver of the new area of digitalization. The digitalization helps the automotive industry to turn faster and more efficiently their ideas into successful vehicles. The requirements and demands of the Automotive Parts Manufacturing industry are as manifold as the new opportunities created through digitalization. UYEE also provides the services of custom automotive parts.

How to Choose Best CNC Auto Parts:

1)The environment in which your machine is going to be used and installed has the biggest impact on the material selection. Such as, if it is going to be used in outdoor environment than stainless steel is suggested as compared to carbon steel. CNC machining allows tight tolerance on part dimensions and in case you are considering having CNC Auto Parts, you will be in a fix. The material you choose has a big impact on the ease of machining and cost effectiveness.

2)Operating temperature, Different materials resistant to high temperature are different. Ranging temperature often trouble the machinery as certain material expand considerably with small relatively changes in ambient temperature, so you need something that is strong and stable to design at the operating temperature.

3)Sometimes heavy materials are not the good choice for the weight sensitive application although they are able to provide stress absorption, good strength by default. There are many other special alloys for choosing like polymers, and other materials that have the tendency to provide tolerance, capability, stress absorption and other needed characteristics.

4)Usually the high strength material requires the carbide titanium, or carbide tooling due to the resistance they are posing in machine. High strength specialty material includes the lightweight type that costs more to the sources. So this is you have to do considering the machine ability and overall cost of the materials. Of course the best strategy is to select the right of Machining Automotive Parts manufacturers.