Titanium is really a transition metal frequently utilised within the aerospace, health, and military businesses. It’s really as strong as steel, however 40 percent lighter. Titanium is ductile and it has a higher melting point, which makes it well suited for extreme heating software.

In the present manufacturing business, titanium and its alloys are principles in aerospace, automotive, medical, and firearm software. This hot metal is more resistant to rust and compounds, is recyclable, and so is excessively strong for the weight loss. But, there are numerous challenges that have to be taken into consideration when machining titanium and selecting the suitable tools and parameters to the career.

But, CNC machining titanium additionally introduces exceptional challenges that accuracy engineers used to machining additional alloys may come across difficult. Here we consider why machining titanium is indeed very hard and unique methods you need to use to find the most useful results when machining titanium.

THE REASONS THAT TITANIUM IS SO POPULAR

While aluminum and aluminum metals were formerly preferred stuff of this aerospace business, newer air craft layouts are making use of titanium and titanium alloys. These substances are also utilised from the industry. The causes of their prevalence comprise lightweight, higher strength, superb fatigue performance and higher immunity to competitive surroundings, staying without degeneration and rust. Titanium parts last longer and offer better results and performance compared to other alloys and substances.

That is a significant reason it really is costlier compared to other alloys. Titanium parts have additional cost consequences as they’re not easy to machine. Titanium is well known for its durability and includes a top strength-to-weight ratio. Additionally, it provides exceptional corrosion resistance and both poor electric stoves.

More over, instead of consume heat, titanium wants to reflect that, which means you’re going to think it is from lowe windows, bouncing straight back heating infrared beams from sunlight.

Concerning appearance, titanium’s color fluctuates based on how far it was shifted. It can include dull grey in raw shape to glistening silver once smooth. The titanium found within our DMLS procedure is currently Ti 6Al4V, additionally called Ti 6 4. It’s mechanical properties like Ti tier 2 3 annealed and it has exemplary electric power.

Workhorse Metals for Machining

If you consider a fantasy group of material faculties such as parts, lightweight and durability spring into mind. Naturally, therefore conduct aluminum and titanium. These two substances tick off other crucial boxes, for example as exceptional resistance to rust and tolerance for heat.

Aluminum’s low specific gravity (2.7 g/cm3) ensures it’s much milder compared to sparks like steel, that will be roughly twice as thick. Although titanium is all about two-thirds weightier than aluminum, its own inherent strength signifies you want it. Actually, you require a small percent of the sum of titanium to find precisely the exact same physical advantage you’d get using aluminum. Titanium is found in aircraft engines, as an instance, as well as in space craft, too. Its potency and lightweight reduction gas expenses.

Aluminum vs. Titanium

Since both substances offer you high durability and low weight, so it is vital that you check in other differentiators when picking which metal to make use of to your own parts.

1, Cost: While titanium adds price, but it can induce value. Lighter-weight parts interpret into gas economies in transport applications, and titanium parts only keep going longer.

2, Strength/Weight: In serious conditions where every gram counts nevertheless, you require strong components, titanium could be your thing to do. Titanium health components, advanced satellite components, fittings, and mounts all triumph just because of this.

3, Corrosion Resistance: Titanium’s corrosion resistance and absence of reactivity causes it to be probably the very biocompatible metal, therefore it is amazing in medical uses, for example as surgical instrumentation. Ti 6 4 additionally supports to polluted surroundings and is commonly utilized in marine software.

4, Thermal Properties: Programs that want high thermal conductivity, for example a heatsink, will gain from aluminum. For high temperature software, titanium’s high melting line benefits software where heat resistance is important, for example as aerospace engine components.

WHY TITANIUM IS SO DIFFICULT TO MACHINE

The most properties which make titanium precision parts with this kind of high-quality alloy will also be the hard material properties which may make it tough to machine. As when utilizing aluminum alloys up to 90 percent of this material could have to be milled and turned off to create the last part. However, you have to know that Titanium metals have a very low Young’s modulus, that induces flexible straight back and forth chatter throughout machining. This will make inferior surface quality become good as the same as the final product. So you can understand that this nearly eliminates the prospect of automating titanium machining.

According to the drawbacks of description, you’ll find methods which produce machining CNC titanium easier and more efficiency

HOW TO MACHINE TITANIUM

As we all know, titanium is super stiff. So machining titanium demands on using coated carbide tools that’ll withstand the stickiness of this kind of metal and divide the cutter chips that are long. The application coating also can help to manage heat generated by CNC machining process.

Been Keeping radial engagement low is quite crucial to counter act the consequences of heat creation and work-hardening trend. Increasing the range of flutes at the end of milling titanium might help better to counteract the reduce feed to boost productivity hugely. Due to application of high pressure helps reduce damage and heat to the cutting tool. The purpose is to lessen the contact period of this tool, and also better prolong and make sense the cutting tool life.

The procedure used in production is key when machining titanium may also help improve benefits. By using’ scale milling’, arcing at, finishing onto a 45-degree chamfer, employing a second aid cutting tool style, shifting the machine axis thickness, and employing an instrument at 70% smaller in relation to the tool pocket, then, you also can decrease the cutting tool damage and get improved results once machining titanium run.

By carefully assessing the exceptional and special material performances of titanium alloy and also correcting machining methods suitably, you’re able to find the most useful results for the own cutter tool as well as the final titanium item.

Titanium in CNC Milling

CNC milling can be just a handy strategy to system precision titanium parts, to boost the metallic productivity and efficacy, each element or variable throughout the CNC titanium milling procedure ought to be contemplated, for example cutting edge tool, axes or spindles, work piece material types and faculties and instrument holder, fixture, and rust or cutting fluid, and much more. The grinding operations will probably soon be different as a result of varying uses of this CNC titanium milling service. To cut back the advantage wear of gels and also avoid the chance of gas, the cutting rate can not be raised if milling titanium alloys. Ti 6Al-4V titanium metal or titanium level 5 may be your very common Ti metal that accounts for over 1 / 2 of overall use of titanium.

Titanium in CNC Turning

Titanium metal has exceptional cutting faculties in CNC turning because its chemical, mechanical and physical properties. By way of instance, the touch between processors and also front surface is quite short, and also heat generated throughout titanium cutting isn’t simple to be transmitted, that will be concentrated at the leading space and the tiny stove close to the very border, which leading in elevated cutting temperatures. Additionally, the CNC turned titanium parts is processed with stamping, forging, hot rolling as well as also other procedures, forming a delicate and hard irregular surface, that will be quite easy cause the border collapse, even in the event the titanium includes strong chemical predisposition to the tool stuff, it’s simple to generate adhesive spray under the status of elevated temperature and high cutting force per unit space.

INDUSTRIES FOR TITANIUM PARTS

Alloyed titanium is ideal for applications that want springy, anti-corrosion, light weight, temperature-resistant substances. It’s utilized in jewelry, tennis rackets, goalie masks, ribbons, bike frames and surgical tools, along with cellular phones.

Twice as strong as aluminum however just 60 per cent thicker, titanium alloys have been appreciated by aircraft and space craft manufacturing companies. It’s found in everything from aircraft controls and engines to structural components and shooting gear.

Titanium is thought to be probably the most biocompatible metal — maybe not hazardous or harmful to tissue — thanks to its immunity to rust out of physiological fluids. The capacity to bond bone gives it an advantage over substances that want adhesion to keep attached. Titanium implants continue longer, and even bigger forces are essential to divide the bonds connecting them into your system. As a result of the residence, patients using titanium implants may safely undergo MRI tests. Additional medical-related utilizes for titanium comprise:

- Defibrillators

- Drug pumps

- Pacemakers

- Bone growth stimulators

- Left Ventricular Assist Devices, or LVADs

- Battery components

- Neurostimulation Devices

One of those essential capabilities of titanium alloys would be that the capacity to resist extremes. As a result of its survivability, titanium is significantly employed by businesses that operate in harsh surroundings or require high-strength minus the weight or size reduction.

- Aerospace

- Power generation

- Medical

- Petrochemicals

- Water treatment

- Marine

- Oil and gas

- Architectural

- Electronics

- Construction

Why Choose Titanium Machining?

A lot of titanium’s cloth and component design faculties allow it to be costly to system. A significant quantity of stock has to be taken off chief varieties such as forgings, platesand bars, etc.. In certain case, just as far as 50 to 90 percent of the principal form’s weight ultimately ends up as chips. Maximum machining efficacy for titanium alloys will be needed to reduce the prices of stock elimination.

Historically, titanium was regarded as being a material that’s tough to machine. As a result of titanium’s growing acceptance in most businesses, together with the ability gained from innovative fabricators, a wide base of custom titanium manufacturing knowledge today is present. Manufacturers today realize, together with proper procedures, titanium might be manufactured with methods no harder than those useful for machining 316 metal.

Machining of titanium alloys necessitates cutting compels just marginally more than those needed to system steels, but those metals have metallurgical traits which cause them to become marginally harder to machine than steels of equivalent hardness. The beta metals would be the toughest titanium metals to machine. When machining states are selected correctly for a particular metal composition and processing arrangement, affordable production rates of machining may be performed at reasonable cost rates.

Care has to be exercised in order to prevent loss in surface integrity, specially throughout grinding; differently a remarkable reduction in bodily behaviour like fatigue may lead. An break through seems to require the evolution of brand new tool substances.

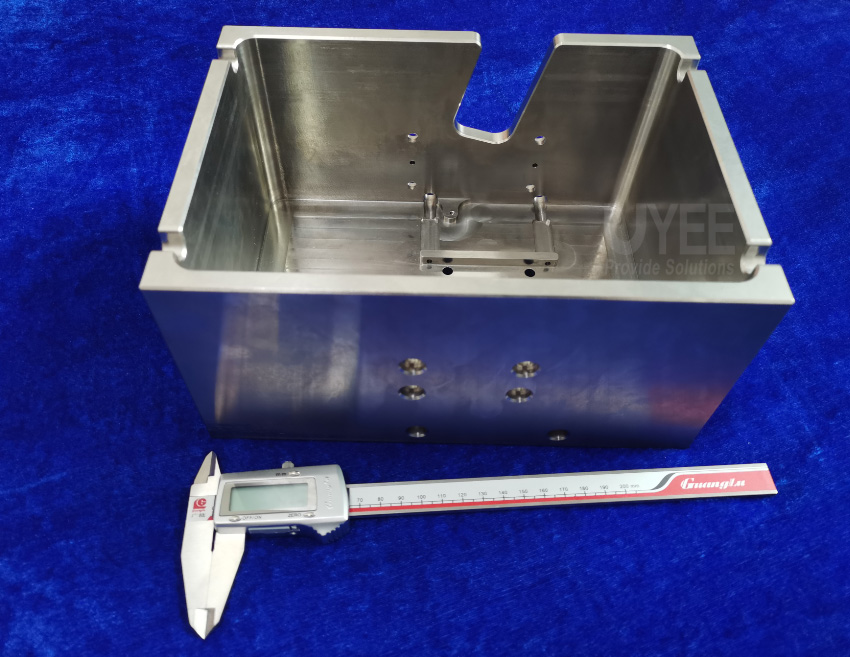

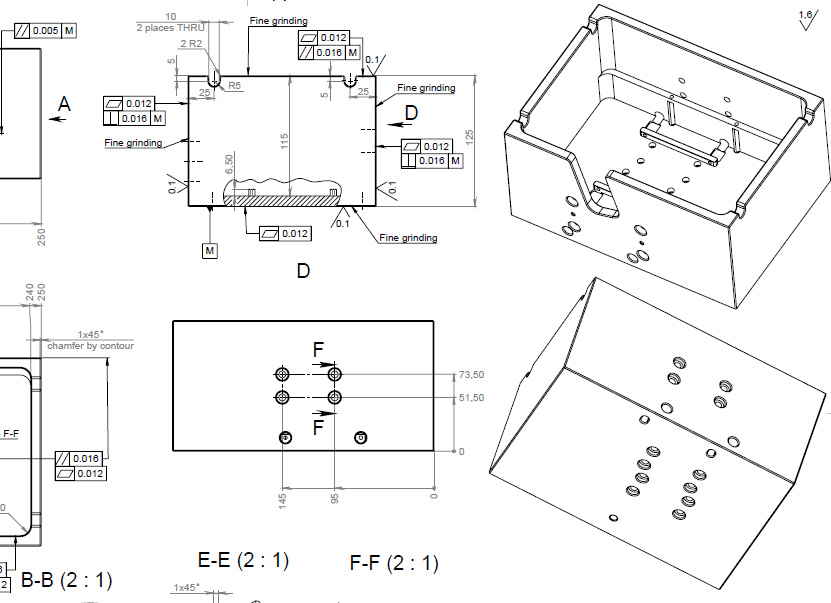

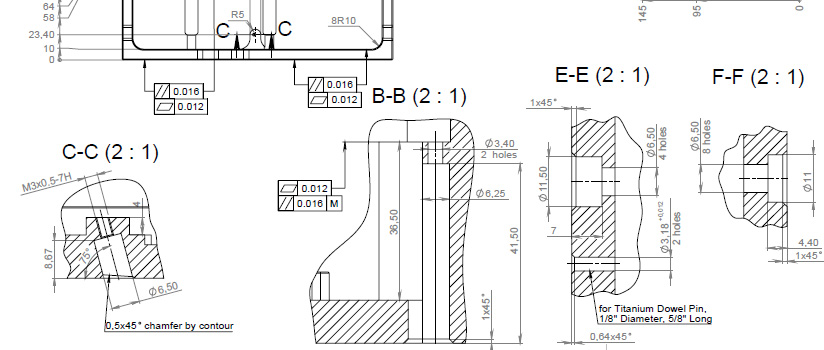

Titanium Machining Case Study

We’ve searched for any range of customers by simply reading throughout the case studies below. From big complex CNC titanium parts for LiDAR device to some collimator with approximately 1, 000 small holes each hole clubbed in another angle compared to moving hole to generate one center point- we reach incredible tolerances”ordinary” machine shops can’t reach. Our dedicated and skilled team, paired with all the ideal CNC titanium machines to be found on the current market, lets us meet the specific specifications (regardless how complex) our customers’ components require. For those who have trouble parts, come on the go to receive your prototype manufactured, or possess complex tolerances additional CNC titanium machinists think hopeless to reach we call us. We’ll do exactly what they could not, which makes the impossible possible.

Even the aerospace, signage, and engraving businesses could be vastly different, but we’ve had success stories across the board. Take a look at titanium machining the case studies below to see how a customized solution was intended to help a peer reviewed in your own industry.

This case showing that the roughness is 0.1 for customer’s request, but that can not be completed because of such a big surface through by grinding. However, after discussed with the customer, what they can accept is 0.8 . So we did it.

SEND US AN INQUIRY