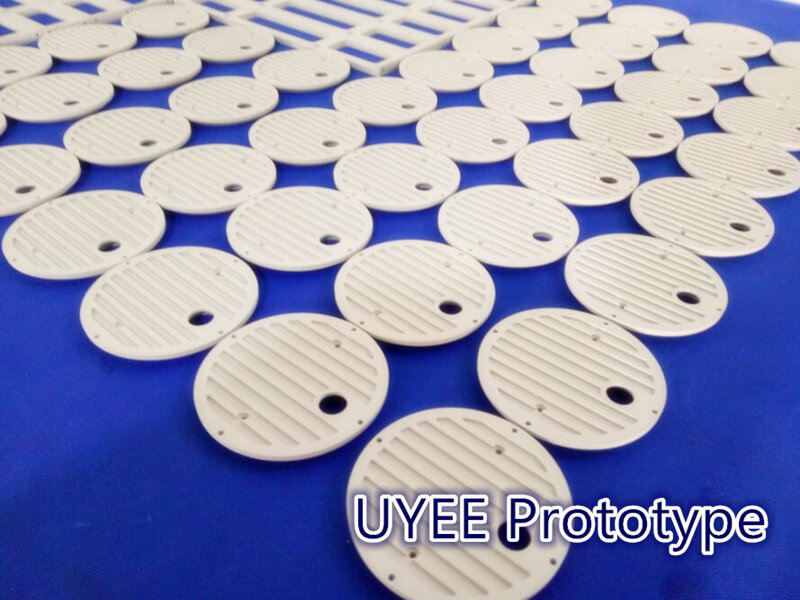

Metal Prototype Machining

The process of drilling and processing of electroplating precision welding technology selection and optimization of the cutting process into the high-speed cutting of the era of CNC programming a few summary.

Drilling machine has numerous models with different sizes. The type of modern machine tool is almost infinite. Some machines can be installed on the table too small, and some machine tools to build a special plant to accommodate the next. Some machines are fairly simple, and some of the machine construction and operation is very complex. These are important for Metal Prototype manufacturing. Regardless of whether the machine is big or small, it’s simple or complex, can be divided into five categories.

1) Drilling

Machine model number, size varies. The type of modern machine tools is almost infinite. Some machines can be installed on the table too small, and some machine tools to build a special plant to accommodate the next. Some machine tools are quite simple, and some of the machine Construction and operation is very complex. Regardless of whether the machine is large or small, is simple or complex, can be divided into five categories, these five categories is to make metal forming five basic methods. Drilling is drilling on solid metal. Use a rotary bit called twist drill. The machine used for drilling is called a drilling machine. Drilling machines also have a variety of models and specifications. In addition to drilling, the drilling machine can also be other processing. When drilling, the workpiece is positioned clamping, fixed; Drill side of the rotation, one side into the workpiece

2) Turning and Boring

Ordinary machine tools are the most common machine tools for turning workpieces. Turning is the removal of metal from the workpiece. While the workpiece is rotating, the tool cuts into the workpiece or cuts it along the workpiece. Boring is a method of machining a hole that has been drilled or cast on a metal workpiece or for further processing. Boring in the lathe is done by rotating the single-edged tool with one side of the workpiece.

3)Machining/Milling

Machining is the use of rotating tools to cut the metal processing, this tool has a number of cutting edge, called the cutter tool .CNC machining and milling is often applied in industry. Actually CNC Metal Prototype maybe the first sample before running mass production. With the rapid development of science and technology and the increasingly fierce economic competition, the rapid renewal of mechanical products, CNC machining technology as a representative of advanced productivity in the field of machinery and related industries play an important role in the machinery manufacturing competition, its Essence is the competition of CNC technology. So master the advanced CNC manufacturing technology is very important. The numerical control of the machining process analysis and design as the starting point, focus on analysis of parts, Content and processing of some special problems on the basis of the process, control the error in the NC programming process, thus greatly reducing the processing time and improve efficiency, with the rapid development of science and technology and economic competition is becoming increasingly fierce, mechanical products Update faster and faster, CNC costs, but also improve the quality of products and grades.

4)Grinding

Grinding is the use of a grinding wheel called grinding wheel to remove the metal processing methods. Grinding the workpiece for finishing, after processing the workpiece size is accurate, smooth surface. When grinding a round workpiece, the workpiece rotates one side and rotates toward the rotating wheel give. When grinding flat workpieces, the workpiece is reciprocated in a rotating grinding wheel. The grinding process is often used for passing Heat-treated hard workpieces for final finishing to achieve precise dimensions.

5)Black planer planning, gantry planning and cutting machine cutting

These processes use single-edged tooling to produce a precise plane. We should understand the difference between the black planer, the planer and the bed. When machining with a dovetel, the workpiece feeds the tool and the tool moves back and forth on the workpiece when machining with gantry, the tool cuts into the workpiece or feeds the workpiece, and the workpiece moves back and forth under the tool. The cutting process is similar to the black heading process.

The lathe is actually a vertical shaper, but its tool is up and down. When cutting, the workpiece, such as the direction of the tool to the movement, according to the type of workpiece is different: sometimes linear, sometimes curved. The bed is vertical. It’s the useful methods to manufacture Prototype Metal Parts and fix some complex issues during production process.