The design phase in contemporary manufacturing is no longer solely concerned with form and function; it serves as the foundation for quality, performance, reliability, and manufacturability. It is imperative to guarantee high quality during the design phase to prevent costly errors in the future, regardless of whether you are developing a straightforward mechanical component or a complex aerospace part.

This article delineates the fundamental steps, principles, and best practices that are necessary to guarantee a high-quality product during the design of a part, regardless of the industry or application.

What is the Reason for the Beginning of Quality at the Design Stage?

It is estimated that the design phase is responsible for determining up to 70% of a product’s total lifecycle cost and qualitative performance. Poor design can result in:

- Inefficiencies in the manufacturing process

- Material depletion

- Product recalls or malfunctions

- Increased customer complaints

- Issues related to regulatory compliance

This is the reason why organizations are increasingly adopting Design for Excellence (DfX) strategies, including Design for Manufacturability (DfM), Design for Assembly (DfA), and Design for Quality (DfQ), to guarantee superior outcomes.

Key Steps to Guarantee a High-Quality Product During the Design Process

- Comprehend the Requirements Completely. Begin by establishing a comprehensive comprehension of:

Functional requirements: What functions does the component need to perform?

Environmental conditions: Will it be subjected to pressure, chemicals, heat, or moisture?

Mechanical loads: Is the component experiencing fatigue, vibration, torque, or stress?

Aesthetic requirements: Are visual aspects significant?

Industry-specific certifications (ISO, ASTM, FDA, etc.): Regulatory and compliance standards

The designer, client, and production team are guaranteed to be in agreement by documenting and validating these requirements.

- Collaborate Across Disciplines Early

Designers frequently operate independently; however, they generate superior components through collaborative endeavors:

- Engineers who specialize in design

- Engineers who specialize in manufacturing

- Teams responsible for quality assurance

- Professionals in the field of supply chain

- End-users and customers

Concurrent engineering enables stakeholders to identify prospective issues at an early stage, resulting in faster development, more informed decisions, and fewer design changes in the future.

- Implement the principles of Design for Manufacturability (DfM)

There are several best practices for DfM, including:

- When feasible, implement conventional dimensions and capabilities.

- Refrain from employing strict tolerances unless they are absolutely necessary

- Reduce the quantity of intricate features

- Develop components that necessitate minimal preparations for machining or molding.

This method enhances consistency and repeatability, accelerates production, and reduces costs.

- Adopt Design Validation Tools and Simulations

Conduct simulations and tests to verify the integrity of the design prior to the commencement of physical production.

Finite element analysis (FEA): Evaluates stress, strain, and deformation in response to stresses

Computational Fluid Dynamics (CFD): Evaluates the flow of fluid or air for components that involve dynamics.

Thermal simulations: Assess behavior in response to temperature fluctuations.

Motion analysis: For assemblies or components that are capable of moving

These tools assist designers in identifying potential failure points, vulnerabilities, or overengineered areas, thereby ensuring a balance between cost and performance.

- Conduct a tolerance analysis.

The permissible degree of deviation from the specified dimensions is determined by tolerances. One of the most significant causes of quality failure in the manufacturing process is improper tolerancing.

Suggestions for the development of effective tolerances:

- For the sake of clarity, implement Geometric Dimensioning and Tolerancing (GD&T).

- Comprehend the capabilities of manufacturing processes

- Steer clear of excessively restrictive tolerances that increase costs.

- Employ stack-up analysis to guarantee that assemblies are both functional and well-fitted.

- The selection of materials is essential.

The utilization of an inappropriate material can result in the failure of an otherwise well-designed component. Select materials according to:

- Mechanical properties: Resistance to fatigue, durability, and strength

- Thermal resistance: Conductivity and expansion

- Corrosion and degradation are examples of chemical resistance.

- Cost and availability: Bulk pricing, local procurement

- Recyclability and sustainability

Additionally, take into account the post-processing requirements, such as anodizing, thermal treatment, or coating, which have an impact on both cost and performance.

- Prototype Prior to the Design’s Finalization

Physical validation of the component is facilitated by prototyping. Alternatives consist of:

- 3D printed models for the purpose of determining form and fit

- Prototypes that are functional and utilize genuine production materials

- CNC-machined test components for the purpose of performance validation

Before full-scale production commences, rapid prototyping mitigates risks and guarantees that the component meets real-world requirements.

- Execute Design Reviews and Checklists

Every milestone should include formal design evaluations. Incorporate a design checklist that encompasses the following:

- Functionality

- Capability to manufacture

- Cost objectives

- Standards of compliance

- Tolerance

- Risks and hazards

Utilize Failure Mode and Effects Analysis (FMEA) to predict potential issues and devise strategies to mitigate them.

- Implement Feedback Loops

Design should never be static. Post-launch feedback from manufacturing teams, QA personnel, and customers can provide invaluable insights.

- Establish systems for the collection of defect data.

- Examine customer complaints or warranty claims

- Encourage employees to provide feedback on the production floor.

- Utilize this data to enhance subsequent iterations or comparable products.

- Implement Version Control and Documentation

It is imperative to preserve a precise design history and revision control system in order to:

- Guaranteeing traceability

- Avoiding outmoded illustrations

- Adhering to regulations and audits

- Facilitating teamwork

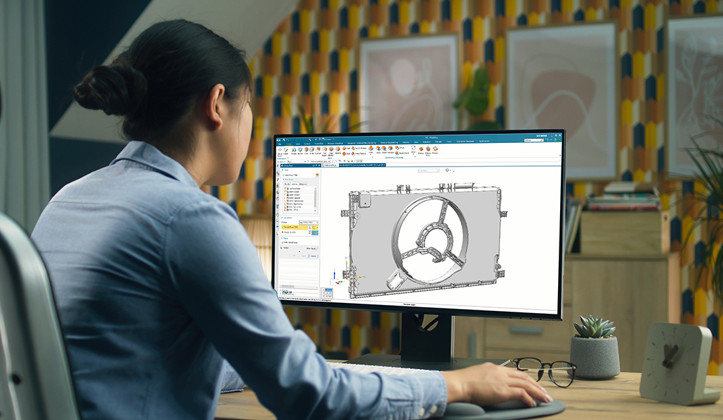

Product Lifecycle Management (PLM) systems or cloud-based platforms (e.g., Fusion 360, SolidWorks PDM) facilitate the efficient management of revisions and changes.

Common Errors That Result in Subpar Parts

- Designs that are excessively complicated and contain superfluous features

- Disregarding manufacturing constraints during the initial phases of the design process

- The absence of standardized components renders it challenging to restore or replace them.

- Neglecting to conduct tests under realistic circumstances

- Miscommunication resulting from unclear or ambiguous documentation

By avoiding these traps, the likelihood of generating a product that is both high-quality and free of defects can be significantly increased.

Real-World Example: Design of Automotive Components

Consistent failures of a brake lever bracket were encountered by an automotive supplier. Subsequent to the redesign:

- During the prototype design phase, they worked in conjunction with the stamping vendor.

- The bracket was subjected to a finite element analysis to verify its performance under impact loads.

- The design was modified to reduce weight by 20% without compromising strength.

In order to mitigate expenses, tolerances were relaxed to the greatest extent feasible. The outcome? There were no failures in the production of more than one million units.

Conclusion

Clear comprehension, intelligent planning, and cross-functional collaboration are the outcomes of high-quality part design. Each stage is essential, from the definition of requirements and the selection of appropriate materials to the optimization of manufacturing and the simulation of stress.

In addition to guaranteeing regulatory conformance, customer satisfaction, and long-term success, the investment of time and effort during the design phase minimizes defects. Designing with quality in mind is not an option in the current competitive and quality-conscious market; it is essential.