One of the most precious metal utilized in precision engineering is nickel and its alloys. The aerospace, oil and gas, nuclear, and chemical processing sectors rely heavily on nickel alloys because of its exceptional corrosion resistance, high-temperature strength, and toughness. However, the process of machining nickel alloys is not simple. They are challenging to cut due to their hardness, work-hardening properties, and limited heat conductivity; this calls for sophisticated CNC methods, specialized equipment, and well-thought-out machining plans.

This blog provides a thorough grasp of how contemporary manufacturing overcomes the difficulties posed by these difficult metals by examining the procedures, machinability properties, and uses of nickel CNC machining.

Understanding Alloys and Nickel

Nickel is a multipurpose metal that has outstanding resistance to oxidation and corrosion along with strength and ductility. The most widely used alloys based on nickel are:

Inconel (Ni-Cr): High temperature and oxidation resistance make a valuable material for gas turbines and aircraft.

Monel (Ni-Cu): Excellent resistance to corrosion in chemical and marine conditions.

hastelloy (Ni-Mo-Cr): It has outstanding resistance to potent oxidizers and acids.

Alloys Nimonic and Rene: It is renowned for their ability to retain strength at high temperatures.

When traditional materials, such as stainless steel, are unable to endure high temperatures, high pressures, or corrosive conditions, these alloys are employed.

These same characteristics, however, make nickel alloys challenging to machine since they demand exact process control, produce strong cutting forces, and quickly wear down tools.

Nickel Alloy CNC Machining Operations

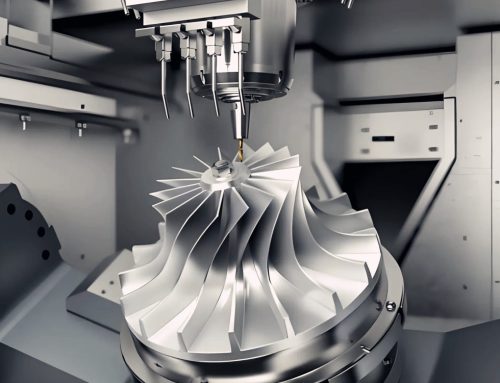

The processing of nickel and its alloys has been completely transformed by CNC (Computer Numerical Control) machining. CNC systems’ accuracy, repeatability, and automation capabilities enable producers to minimize tool wear while achieving complicated geometries with great precision.

The most popular CNC procedures for nickel alloys are as follows:

- The use of CNC turning

used to make cylindrical parts, such as fasteners and turbine shafts.

Problems: Heat accumulation and strong cutting forces.

Optimal cutting parameters, positive rake angles, and coated carbide or ceramic inserts are examples of best practices. Continuous, high-pressure coolants are ideal.

- The use of CNC milling

involves making intricate shapes, including compressor blades and engine parts, by cutting along several axes.

TiAlN-coated solid carbide end mills are suggested tools.

Method: To keep tools sharp and minimize heat production, use climb milling.

- The use of CNC drilling

Nickel alloys are difficult to drill because of work-hardening and chip evacuation problems.

Methods: Coolant-through drills, low feed rates, and peck drilling are frequently employed.

- Computer-aided design

Grinding is used after machining to attain excellent surface polish and tight tolerances. Soft-grade wheels and constant dressing are necessary since nickel’s hardness can result in wheel glazing.

- Electric Discharge Machining, or EDM

EDM is frequently used for complex features and ultra-hard nickel alloys. It eliminates tool wear issues by using electrical discharges instead of mechanical cutting.

Nickel Alloy Machinability

Alloys of nickel are categorized as “difficult-to-machine” substances. Compared to aluminum or carbon steels, they are much less machinable. Among the main causes are:

Work Hardening: When cut, nickel alloys harden quickly, enhancing resistance in later passes.

Low Thermal Conductivity: Rapid tool damage results from heat accumulation at the cutting edge.

High Strength: Causes more tool deflection and cutting forces.

Adhesion Tendency: A built-up edge is created when nickel tends to fuse onto the cutting tool.

Achieving dimensional precision is made more difficult by elastic recovery.

Ratings of Machinability

Compared to free-machining steel, Inconel 718 has a machinability of 10–15%.

20–25% machinability for Monel 400.

Hastelloy C-276: machinability range: 12–18%.

Increasing Machinability

Several process optimizations are necessary to get beyond these obstacles:

Use ceramic tools with great heat resistance, carbide tools, or CBN (Cubic Boron Nitride) tools.

Cutting parameters: Moderate feed rates combined with low cutting speeds (20–60 m/min) avoid overheating.

Coolant/lubrication: Chip adhesion and temperature rise are reduced by high-pressure, flood coolant.

Tool Geometry: Positive rake angles and sharp edges lessen cutting forces.

Adaptive Machining Strategies: To ensure uniformity, real-time feedback systems modify feed and speed.

Advanced CNC Methods for Machining Nickel

As manufacturing has advanced, a number of CNC techniques have been developed to improve productivity and machinability:

High-speed machining, or HSM, can reduce heat buildup even though it seems contradictory for hard materials. This is achieved by using high feed rates and shallow depths of cut.

Liquid nitrogen cooling significantly lowers temperature and tool wear in cryogenic machining.

In ultrasonic-assisted machining, vibrations lessen cutting forces and aid in chip breaking.

Hybrid EDM-CNC Systems: For ultra-hard nickel alloys, combine CNC freedom with EDM precision.

Toolpath Optimization (CAM Software): This software uses advanced simulation to calculate the most efficient machining parameters and anticipate tool wear zones.

Applications for CNC Machining of Nickel

Because of their strength and ability to withstand corrosion, nickel alloys are essential in sectors where performance in harsh environments is crucial.

- The Aerospace Sector

Superalloys based on nickel, such as Inconel 718 and 625, are utilized for:

combustion chambers, discs, and turbine blades

Jet engine components and exhaust systems

Seals, casings, and fasteners

These alloys are mechanically stable even at temperatures higher than 1000°C.

- The Oil and Gas Industry

It is necessary for parts like drill collars, pumps, and valves to be resistant to corrosion from sour gasses and seawater. Nickel alloys that perform well under these circumstances include Inconel and Monel.

- Generation of Power

Because of their strong radiation and heat resistance, they are utilized in nuclear reactors, heat exchangers, and gas turbines.

- The Petrochemical and Chemical Sector

Reactors, heat exchangers, and piping systems that deal with strong acids and alkalis are perfect for nickel alloys.

- Engineering for the Sea

Because monel alloys don’t corrode in seawater, they can be used for hull fittings, heat exchangers, and propeller shafts.

- Dental and Medical Equipment

Stents, orthodontic wires, and surgical instruments all use nickel-titanium (Nitinol) because of its shape memory and biocompatibility.

Sustainability and Prospects for the Future

Nickel recycling and additive-subtractive hybrid manufacturing are becoming more popular as sustainability becomes a greater priority. By only milling where extreme precision is required, CNC machining combined with 3D printing can save waste.

To ensure optimum production with lowest waste, CNC machining systems are also using artificial intelligence and machine learning to predict tool wear, optimize cutting conditions, and decrease downtime.

Conclusion

The process of CNC machining nickel is challenging but rewarding. Because of their strength, resistance to heat, and ability to prevent corrosion, nickel alloys are crucial for industries that work in harsh conditions. However, to attain accuracy and cost effectiveness, their low machinability necessitates careful design, sophisticated tooling, and contemporary CNC processes.

The difficulties of machining nickel alloys are being progressively resolved by ongoing advancements including cryogenic cooling, AI-driven toolpath optimization, and hybrid machining, which pave the way for more effective, dependable, and environmentally friendly production in high-performance industries.