A computer numerical control CNC manufacturing is used to deliver for the industrial parts or molds. As technology has advanced, so has the capabilities of these machines and are available in different variants. Those who are interested in programming or operate this equipment can receive technical training.

CNC machines coming from manual cnc mill machines. Numerical controls were added to mills in 1950. In the 1960s and 1970s, became increasingly added more powerful computer controls. Because both the industrial and computer technology has evolved, the machines have become more sophisticated, and are now able to perform highly complex cnc machining services and machining tasks.

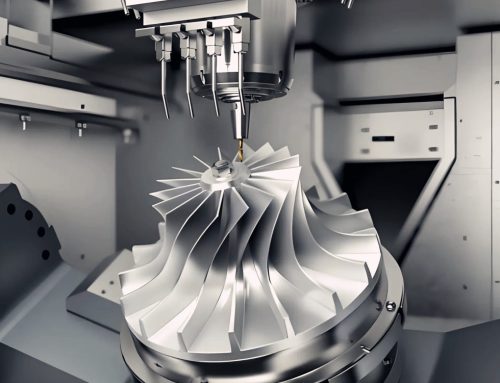

The CNC milling centers are pieces of industrial equipment with solid materials, such as metals and plastics. Equipment normally permanently edit the material in place and other tools to move the material, removing portions thereof. These precise movements and their speeds are programmed in the Machine’s computer. The working parts of a CNC machining are usually locked in metal housing and a door that allows the operator to access the device and tools.

Various processing stations have the possibility to work in different axes, or airplanes. Some common examples are the y-axis, which is forward and backward, the x-axis, the left and right, and z-axis, which refers to vertical movement. The machines can be described by the axis in which it may cooperate, for instance horizontally or vertically. A CNC machining center can be sophisticated enough to work in multiple axes. Such as, now it has 4 axis and 5 axis.

The machines can produce actual machined parts, or may be used to make molds, which are in turn used in the production to cut shaped parts. They make use of different types of tools for various operations, such as tapping, boring, drilling, and to carry out, in order to create the required part or mold. Machining centers can produce parts within a very tight tolerance, which refers to the sections standard dimensions and permissible deviations from the norm.

UYEE CNC machining technology has been around for 12 years. Known for metal processing of the highest precision. We produce ready-to-install CNC turning and CNC machining parts in small- and large series for various industrial sectors. The strengths of UYEE CNC machining technology lie in the combination of experience, know-how and expertise Reliability. Innovative solutions and flexible production structures as well as our highly qualified Employee estate and a state-of-the-art machine park make us the perfect one Partner for demanding tasks.

UYEE CNC machining technology produces turning and milling parts made of steel, stainless steel, aluminum and plastic. Our core competencies lie in the production of small and large series. Client-specific products as well as ready-to-use end products belong to our services.

We manufacture products of the highest quality and precision for various industrial sectors, such as the automotive industry, medical technology or machine and tooling manufacture. Through our flexible machine park and our years of experience we are able to serve a very wide range of products while at the same time offering your very special Requirements.