Lean manufacturing is a methodical framework for the elimination of waste from a manufacturing system, or value stream, without compromising productivity. When we talk about lean manufacturing, the first name that comes to everyone’s mind is Toyota. It was the first to introduce lean manufacturing, which has since become a fundamental component of contemporary production methodologies. In conjunction with state-of-the-art technologies such as 3D printing and CNC machining, Lean principles can unleash unparalleled levels of sustainability, customization, and efficiency.

In this blog, we will tell you about the integration of Lean manufacturing into CNC machining and 3D printing, the advantages it provides, and the methods by which companies can implement these practices to achieve more sustainable and intelligent production techniques.

What is the definition of Lean Manufacturing?

Lean manufacturing is a methodical approach that is dedicated to the reduction of waste without sacrificing quality or productivity. Emphasis is placed on:

- Value from the customer’s standpoint

- Elimination of non-value-added activities (waste)

- Continuous improvement (Kaizen)

- Just-in-Time (JIT) production

- Stable processes and standardized tasks

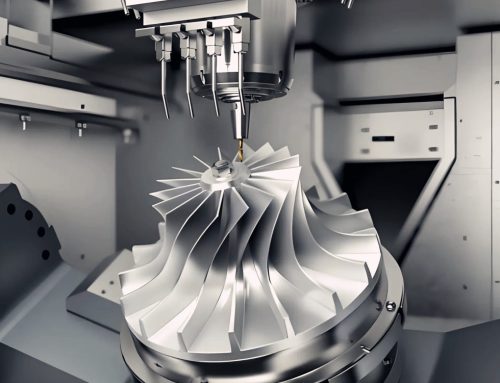

The Application of Core Lean Principles to CNC Machining and 3D Printing

- Waste Elimination .

There are seven conventional forms of waste: overproduction, waiting, transporting, overprocessing, inventory, motion, and defects. These wastes can be minimized through the optimization of both 3D printing and CNC machining.

3D Printing: Decreases material waste by constructing components layer by layer (additive). It is possible to digitally modify designs in order to prevent blunders prior to production.

CNC Machining: Subtractive processes frequently generate material waste; however, waste can be reduced through Lean optimization, such as optimizing tool paths and nesting methods.

- Kaizen (Continuous Improvement)

Teams are able to make iterative enhancements by continuously monitoring performance, quality, and efficiency in both 3D printing and CNC environments.

Real-time data on machine performance can be obtained by integrating sensors and IoT tools.

Digital feedback channels facilitate the rapid identification and resolution of quality issues.

- Quality Built-In

Lean prioritizes quality throughout the entire process, as opposed to post-process inspections.

3D printers are capable of self-monitoring through the use of software to identify anomalies.

In-process inspection tools can be incorporated into CNC machines to guarantee that errors are identified at the outset of the production cycle.

Advantages of Lean in CNC Machining and 3D Printing

- Decreased Lead Times

Manufacturers can substantially reduce lead times by optimizing workflows and eliminating constraints. The rapid prototyping capabilities of 3D printing and the automation of CNC are complementary to Lean strategies in order to expedite turnover.

- Reduced Operational Expenses

Lean methods assist in the identification and elimination of wasteful practices. With appropriate optimization:

- Tool wear and delays are diminished by CNC operations.

- 3D printing reduces waste and consumes less energy per part.

- Improved Quality of Output

Both 3D printing and CNC machining generate components with reduced defects and more precise tolerances by means of feedback loops, process monitoring, and standardized work.

- Flexibility and Scalability

Agile production is facilitated by lean principles. CNC machining is capable of adapting to new tasks with minimal downtime, while 3D printing can rapidly transition from prototyping to production.

Lean Applications in 3D Printing: A Practical Guide

Design for Additive Manufacturing

Engineers can generate more durable components with less waste by employing generative design and topology optimization.

Digital Inventory

Digital storage and on-demand printing of components are viable alternatives to physical inventory storage. This is in ideal harmony with Lean’s objective of decreasing excess inventory.

Automation of Workflow

The time from design to part delivery is reduced by incorporating design, slicing, and print operations into an automated pipeline.

Practical Lean Applications in CNC Machining

Optimization of Tool Paths

Machining time and material waste are diminished by optimizing tool trajectories with CAM software. Tool life is also extended as a result of reduced tool movement.

Cellular Manufacturing

The reduction of movement and the enhancement of flow—key Lean objectives—can be achieved by organizing CNC machines and operators by product type or process.

Preventive Maintenance

Machine delay that is not anticipated is a substantial source of waste. Total Productive Maintenance (TPM) is facilitated by Lean, which guarantees that machines are consistently prepared for production.

Integrating CNC Machining and 3D Printing in a Lean Environment

A potent hybrid production model is established when they are strategically incorporated in accordance with Lean principles.

- The use of 3D printing for rapid prototyping facilitates the rapid iteration of designs.

- High-precision finishing is achieved through CNC machining, which completes components.

- Lean scheduling tools can optimize the selection of parts to print and machine based on the complexity, volume, and material requirements.

- This synergy leads to manufacturing systems that are more cost-effective, agile, and customer-centric.

Obstacles to the Implementation of Lean in Advanced Manufacturing

Although the advantages are evident, the application of Lean principles to high-tech processes such as CNC manufacturing and 3D printing is not without its obstacles:

- The initial setup costs for automation and monitoring tools are high.

- Requirement for personnel who are proficient in Lean methodology and technology

- Resistance to change management in conventional manufacturing environments

- Complicated integration of new tools with legacy systems

These obstacles are being addressed more frequently through industry-wide collaboration, government incentives, and training.

Steps to Implement Lean in Your CNC and 3D Printing Shop

Perform a Value Stream Map

Highlight non-value-added activities and identify each step in your production process.

Begin with the 5S (Sort, Set in order, Shine, Standardize, Sustain) method, which is a fundamental Lean practice that assists in the preservation of efficient, organized workspaces.

Establish Unambiguous Key Performance Indicators

Scrap rate, lead time, first-pass yield, and OEE (Overall Equipment Effectiveness) are essential metrics for monitoring progress.

Provide Training to Your Staff

It is imperative that all individuals, from machine operators to managers, comprehend the principles of Lean and their significance in the process of continuous improvement.

Utilize technology

Utilize ERP systems, data analytics, and digital twins to facilitate real-time decision-making and optimization.

The Future of Advanced Manufacturing + Lean

Lean manufacturing will become even more potent as technologies such as AI, machine learning, and IoT become more accessible. Predictive maintenance, adaptive scheduling, and real-time quality control will expand the limits of what is feasible in CNC machining and 3D printing systems.

Companies that adopt this fusion will not only enhance efficiency and reduce costs but also provide customers with superior value in a more sustainable and expedited manner.

Conclusion

Lean manufacturing when combined with the transformative capabilities of 3D printing and CNC machining, creates a production environment that is more agile, future-ready, and intelligent.

Whether you are a global enterprise with advanced CNC facilities or a startup that utilizes desktop 3D printers, Lean principles can enhance your operations and assist you in thriving in the competitive manufacturing landscape of today.